Impact Toughness & Wear Resistance—MC Nylon’s Two Superpowers Explained

2025-07-27

Intro

A forklift accidentally slams into a pallet slider. A standard plastic insert shatters on the spot, while the MC Nylon part shows only a faint white mark. Where does this “can’t‑break‑me” ability come from? Two simple lab tests and real‑world examples will make the answer crystal‑clear.

1 What Really Measures “Impact Toughness”?

Engineers look at impact strength (kJ/m²; higher = tougher). Typical numbers:

MC Nylon: ≥ 60 kJ/m²

Standard PA6: ~ 35 kJ/m²

POM (Delrin): ~ 20 kJ/m²

Think of MC Nylon as that sports water bottle you can toss on the floor without cracking.

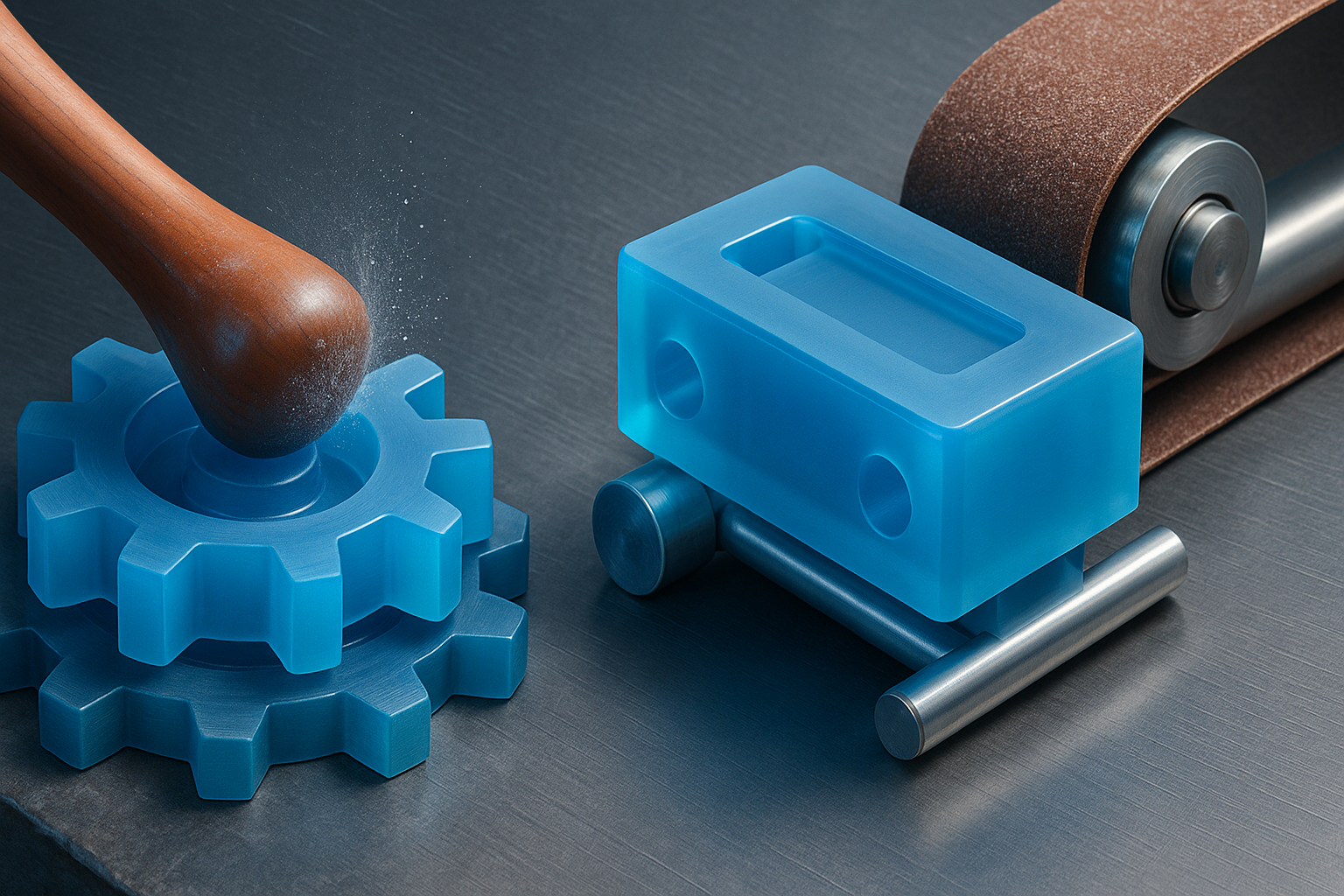

2 Test A: The Baseball‑Bat Impact

Setup: Identical strip samples, whacked side‑on with a baseball bat.

Result: POM snaps in two; MC Nylon only shows a stress‑whitened mark—fully intact.

Takeaway: Switch pallet sliders, machine guards, or bumper strips to MC Nylon and cut unplanned downtime.

3 How Do We Judge Wear Resistance?

Enter the wear index (lower = longer‑lasting). Results:

MC Nylon: ≈ 0.25

Standard PA6: ≈ 0.40

Oiled steel (reference): ≈ 0.20

If shoe soles were made of MC Nylon, they’d still look new after a marathon.

4 Test B: Sand‑Belt Abrasion

Setup: Press each sample against 120‑grit sandpaper under a 50 N load for one minute.

Result: MC Nylon loses 0.02 g; PA6 loses 0.05 g—over twice as much material gone.

Applications: Conveyor rollers, chain guides, gears—any high‑cycle part runs longer with MC Nylon.

5 Turning Toughness & Wear Resistance into Savings

Replace metal or standard plastic guides with MC Nylon and you can:

Cut crash‑related stoppages by ~50 %

Stretch maintenance intervals by ~30 %

On a 24 × 7 line, that’s thousands of dollars in spare‑part and labor savings each year. Design tips: round sharp edges and leave a reasonable safety factor to unlock the full benefit.

Wrap‑Up & CTA

High impact strength plus a low wear index—MC Nylon really is both “hard to break” and “hard to wear out.”

Want to prove it on your own equipment? Click below for free test samples and a 24‑hour toughness & wear evaluation tailored to your project!

TAG:

Related News

Discover the Wonders of Cast Nylon: A Comprehensive Guide