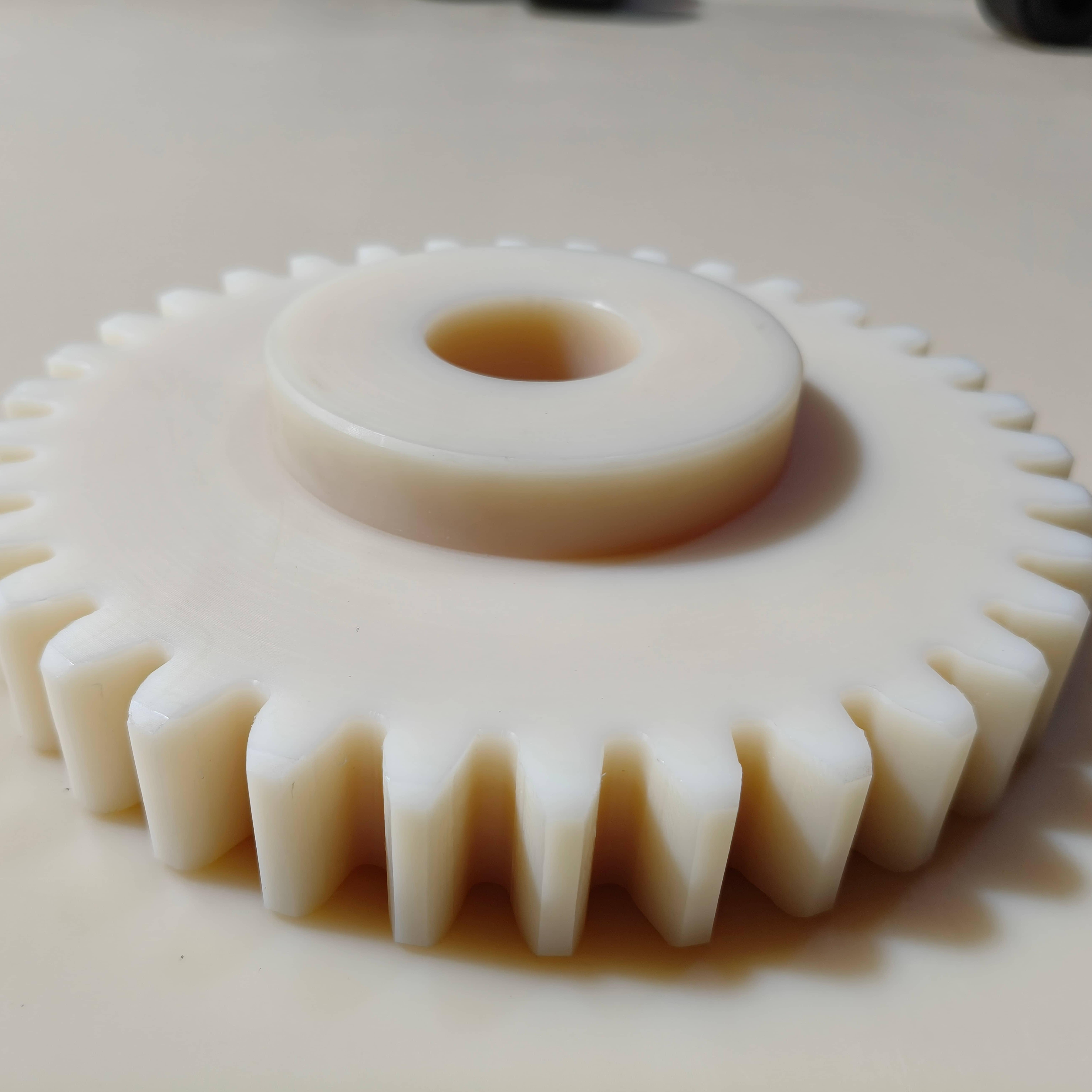

MC Nylon Parts: Lightweight Strength, Whisper-Quiet Operation, Longer Service Life

2025-07-05

Why MC Nylon?

Metal parts weigh tons, rust, and shriek. Regular plastic is quiet but wears out. MC Nylon balances both: strong, light, silent.

What Is MC Nylon?

Think cake. Ordinary nylon is sliced before fully set; MC Nylon cures whole, letting chains stretch longer, so the block is denser and tougher.

Five Everyday Benefits

Featherweight — ≈¹⁄₇ bronze weight; saves energy.

Hard-wearing — lasts like sneaker soles.

Self-lubricating — runs months dry.

Impact-safe — bounces at −40 °C.

Chemical-calm — ignores oil, salt, cleaners.

Quick Success Stories

Mine belts: Steel rollers swapped for MC; noise fell from jackhammer to office hum.

Port cranes: Bronze sheaves changed; decks stayed grease-free all year.

Metro cars: Guide shoes switched; each car lost 60 kg, cutting power 2 %.

Three Checks Before Buying

Load — huge loads need glass-fiber grades.

Heat — over 100 °C? Order heat-stable type.

Shrink — casts contract 0.5 %; machine sizes accordingly.

FAQ

Will it swell in water? Moisture pick-up ≤0.6 %; growth tiny.

Can it replace metal everywhere? For sliding, rolling, yes; for hot, high-pressure cores, keep steel.

Best cutting tools? Sharp HSS or carbide; feed fast, spin moderate.

Wrap-Up

MC Nylon trims weight, hushes machines, and cuts downtime. Request a free test piece today and feel the difference.

Key Takeaways

Weight drops up to 85 %.

Noise falls 20–30 dB.

Grease savings slash cleanup costs.

Service life often doubles.

TAG:

Related News

The Power of Composite Materials: Industry Case Studies Unveiled