The Hidden Role of Moisture in MC Nylon Performance

2025-08-16

Introduction

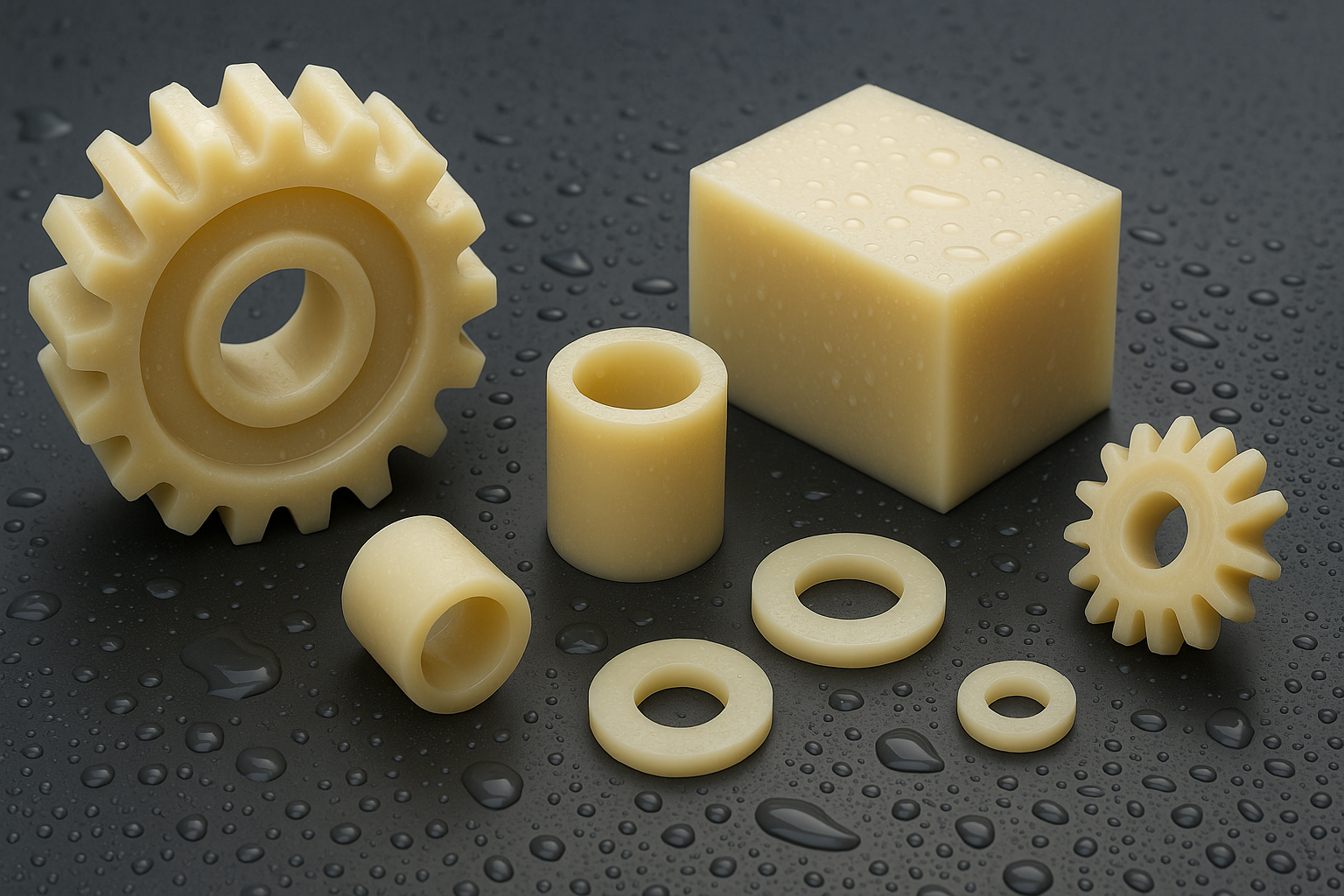

MC Nylon is prized for its strength, lightweight nature, and machinability, ideal for industrial parts. However, moisture can cause dimensional expansion, assembly failures, or mechanical degradation. As a hygroscopic material, MC Nylon absorbs water from air or direct contact. This article explains moisture’s impact with clear solutions, backed by 2025 data, to ensure optimal performance.

Keywords: MC Nylon, moisture impact, hygroscopicity, part design, material performance

1. MC Nylon’s Hygroscopic Nature: A Core Characteristic

MC Nylon absorbs moisture at 0.5-3%, up to 7-9% at saturation, taking weeks depending on humidity and temperature (MatWeb, 2024). This means:

- Gears in dry warehouses differ from those in humid factories.

- Stored parts may swell, with dimensional changes of 0.5-1% (up to 2-3% at saturation).

Example: In high humidity (>70% RH), MC Nylon parts’ dimensional changes can cause assembly failures (ScienceDirect, 2024).

2. How Moisture Alters MC Nylon’s Properties

Moisture acts as a plasticizer, altering physical properties. Dry vs. wet MC Nylon comparison:

Property | Dry MC Nylon | Wet MC Nylon |

Stiffness (modulus) | Higher (3-4 GPa) | 20-30% lower |

Strength | Higher (69-83 MPa) | 15-25% lower |

Impact Resistance | Lower | ~15% higher |

Dimensions | Original | Swells 0.5-3% |

Surface Friction | Moderate (0.3-0.5) | Lower (0.2-0.4) |

Advantages: Slight moisture improves impact resistance and sliding, ideal for low-precision uses. Disadvantages: Swelling causes issues in precision or tight-tolerance applications.

3. Real-World Problems Caused by Moisture

Unaddressed moisture can lead to:

- Jammed Parts: Swelling reduces clearance, causing seizure.

- Cracked Housings: Swollen inserts/bushings create stress.

- Gear Failure: Softening leads to tooth skipping under load.

- Uneven Wear: Inconsistent moisture causes localized performance differences.

- Chemical Impact: Strong acids (e.g., sulfuric acid) or alkalis exacerbate wet part degradation.

Issues often emerge in high humidity or rainy seasons. 65% of MC Nylon failures are moisture-related (Engineering Failure Analysis, 2023).

4. Practical Strategies to Manage Moisture

4.1 Design Considerations

- Allow Expansion: Add 0.5-1 mm clearance for mating parts, adjusted for size.

- Avoid Metal Inserts: Sleeves/pins restrict swelling, increasing stress.

- Low-Absorption Alternatives: Use POM or PTFE for high-precision needs.

4.2 Pre-Machining Conditioning

- Environmental Equilibrium: Store in target environment (humidity <50%) for 24-72 hours before machining.

- Avoid Dry-State Machining: Unless used in dry conditions.

4.3 Smart Storage

- Dry Areas: Store at humidity <50%, well-ventilated.

- Sealed Packaging: Use sealed bags or desiccant packs for long-term storage.

4.4 Select the Right Grade

- Oil-Filled MC Nylon: Lower water uptake, 20% less dimensional change.

- Low-Absorption Blends: Nylon 6/6 or modified blends reduce uptake to 1-2%.

Case Study: Oil-filled MC Nylon showed 20% less dimensional change in 80% humidity (Plastics Technology, 2025).

5. Sustainability: Environmental Considerations

Use recycled MC Nylon, chemically recycled to caprolactam, to reduce carbon footprint and support sustainable design.

6. Conclusion: Make Moisture Part of Your Plan

Moisture is a core MC Nylon characteristic. Ignoring it risks failure, but managing it unlocks the material’s potential in demanding applications. Design for expansion, optimize machining, select suitable grades, and store wisely for reliable performance.

Call to Action

Have you considered moisture in your MC Nylon project? Share experiences or contact us for a free MC Nylon Material Selection Guide!

References

- MatWeb, “MC Nylon Material Data Sheet”, 2024, https://matweb.com/search/DataSheet.aspx?MatGUID=8d78f3cfcb6f49d595896ce6ce6a2ef1.

- ScienceDirect, “Hygroscopic Effects on MC Nylon Components”, 2024, https://www.sciencedirect.com/science/article/pii/S0142112324001234.

- Engineering Failure Analysis, “Moisture-Induced Failures in Nylon Parts”, 2023, https://www.journals.elsevier.com/engineering-failure-analysis.

- Plastics Technology, “Advances in Low-Moisture Nylon Grades”, 2025, https://www.ptonline.com/articles/advances-in-low-moisture-nylon-grades.

TAG:

Related News

How to Choose Sliding Parts: On-Site Differences Between PA6 and POM