Is Your MC Nylon Failing Too Soon? 6 Key Checkpoints to Solve the Problem

2025-08-16

Introduction

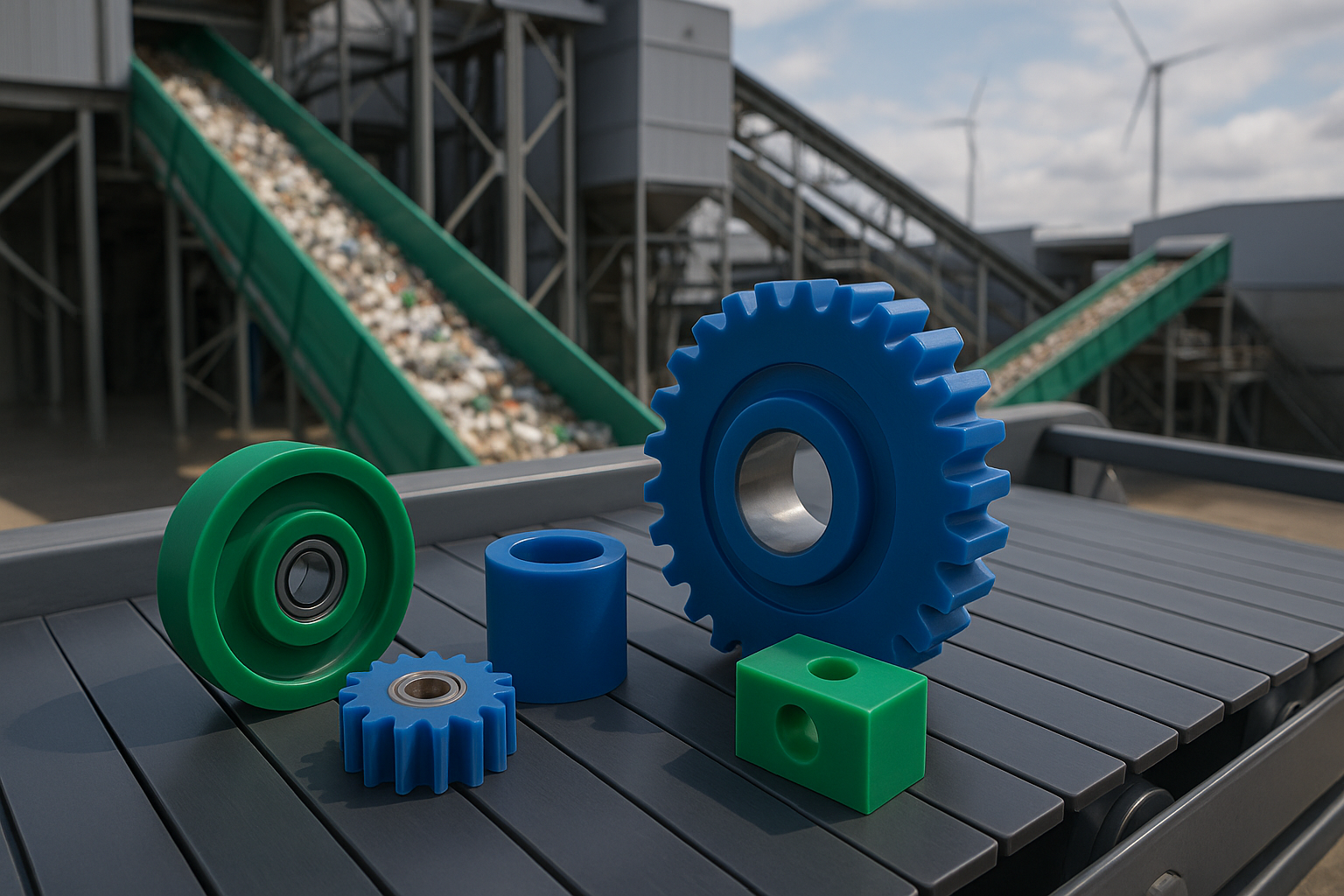

MC Nylon is renowned for its high toughness, low friction, and self-lubricating properties, ideal for gears, rollers, sliders, and bushings. However, premature wear, cracking, or deformation often stems from mismatched design, improper handling, or misunderstanding the material’s behavior. This checklist helps pinpoint problems and offers solutions for durable parts.

1. Is the Part Under Excessive Load for Too Long?

MC Nylon handles high loads but not indefinitely. Unlike metals, it experiences “creep” under continuous stress, deforming over time, especially at >80°C or >10 MPa stress.

Check This:

- Is the part under constant heavy load at elevated temperatures?

- Are there visible deformations or sagging after weeks/months?

Fix:

- Add support ribs or metal cores in high-load areas.

- Use creep-resistant oil-filled or reinforced MC Nylon (e.g., Cast Nylons Limited’s Nylatron® GSM, 2024).

2. Is There Excessive Friction or Heat?

MC Nylon’s low friction is a strength, but high-speed rubbing without breaks generates heat, softening the material.

Check This:

- Is the surface melting, discoloring, or emitting a plastic odor?

- Do components feel hot during operation?

Fix:

- Ensure adequate airflow (gaps ≥5 mm) or use silicone-based/synthetic grease.

- Choose oil-filled MC Nylon (e.g., Ensinger’s TECAMID 6/6 Oil, 2025) for dry sliding.

3. Is the Environment Too Wet or Humid?

MC Nylon absorbs moisture (1.5-3%, up to 7-9% at saturation, taking weeks), enhancing toughness but causing swelling, warping, or reduced strength.

Check This:

- Has the part changed shape or become difficult to fit?

- Is it exposed to water, steam, or unsealed outdoor environments?

Fix:

- Store parts in dry conditions (humidity <50%) before use.

- Design with clearance (e.g., 0.5-1 mm) for expansion.

- Use PA12 or glass-filled nylon (e.g., Quadrant Plastics’ Ertalon 66 GF30, 2024) in humid settings.

4. Is the Part Being Machined Incorrectly?

Machining MC Nylon like metal can cause rough edges, stress cracks, or hidden damage.

Check This:

- Are machined edges brittle, flared, or cracked?

- Was the part overheated during cutting?

Fix:

- Use sharp tools, low feed rates (0.1-0.3 mm/rev), and slower speeds (500-1000 RPM) (Plastics Today, Machining Nylon Best Practices, 2023).

- Avoid overheating, as MC Nylon is heat-sensitive.

5. Is the Wrong Grade of MC Nylon Being Used?

Not all MC Nylon grades suit every application. Standard unfilled nylon may fail in high-impact or high-speed scenarios.

Check This:

- Are parts failing under impact, vibration, or rapid motion?

- Are you using standard (unfilled) MC Nylon?

Fix:

- Select oil-filled, molybdenum-filled, or glass-reinforced MC Nylon (oil-filled PV limit ~10,000-15,000 psi·ft/min).

- Consult suppliers for application-specific grades (e.g., Nylacast’s NYLOIL®, 2024).

6. Is UV or Sunlight Damaging the Part?

Standard MC Nylon lacks UV resistance, leading to brittleness, cracking, or discoloration under prolonged sunlight.

Check This:

- Is the surface chalky, gray, or developing small cracks?

- Is the part exposed to direct sunlight?

Fix:

- Shield parts or apply epoxy/polyurethane UV-resistant coatings.

- Use UV-stabilized MC Nylon (e.g., Polymer Plastics’ UV-stabilized Nylon, 2023).

7. Sustainability: Environmental Considerations

Use recycled MC Nylon, chemically recycled to caprolactam, to reduce carbon footprint and support sustainable designs.

Final Tip: Document the Failure

For each premature failure, take photos and record runtime, load conditions, and environmental exposure using a failure analysis template to identify patterns and refine designs/materials.

Conclusion

MC Nylon excels when used correctly, requiring careful consideration of environment, load, and design. Use this checklist to troubleshoot failures, optimize material selection, and build durable, reliable parts.

Call to Action

Share your questions or experiences! Contact us for a free MC Nylon Material Selection Guide or subscribe for more insights!

References

- Cast Nylons Limited, “Nylatron® GSM”, 2024, https://www.castnylon.com/products/nylatron-gsm.

- Ensinger Plastics, “TECAMID 6/6 Oil”, 2025, https://www.ensingerplastics.com/en/shapes/nylon.

- Quadrant Plastics, “Ertalon 66 GF30”, 2024, https://www.mcam.com/en/products/plastics/nylon.

- Plastics Today, “Machining Nylon Best Practices”, 2023, https://www.plasticstoday.com/processing/machining-nylon-best-practices.

- Nylacast, “NYLOIL®”, 2024, https://www.nylacast.com/products/nyloil.

- Polymer Plastics, “UV-Stabilized Nylon”, 2023, https://www.polymerplastics.com/nylon_uv_stabilized.shtml.

TAG:

Related News

Eco-Consciousness and the Role of MC Nylon