MC Nylon and Practical Environmental Solutions

2025-08-26

Introduction

Industrial sectors today face growing environmental pressures: high energy consumption, material waste, and rising compliance costs. To stay competitive, companies need solutions that balance performance, cost-efficiency, and sustainability. One practical path forward is material innovation—particularly the use of MC Nylon (Monomer Casting Nylon).

Key Industrial Challenges

Metals: Energy-intensive smelting, heavy weight, and corrosion issues.

Conventional plastics: Difficult to recycle, contributing to pollution.

Enterprise pain points: Tighter environmental regulations, rising costs, and pressure across global supply chains.

These challenges make the search for durable, recyclable, and lightweight materials urgent.

The Value of MC Nylon

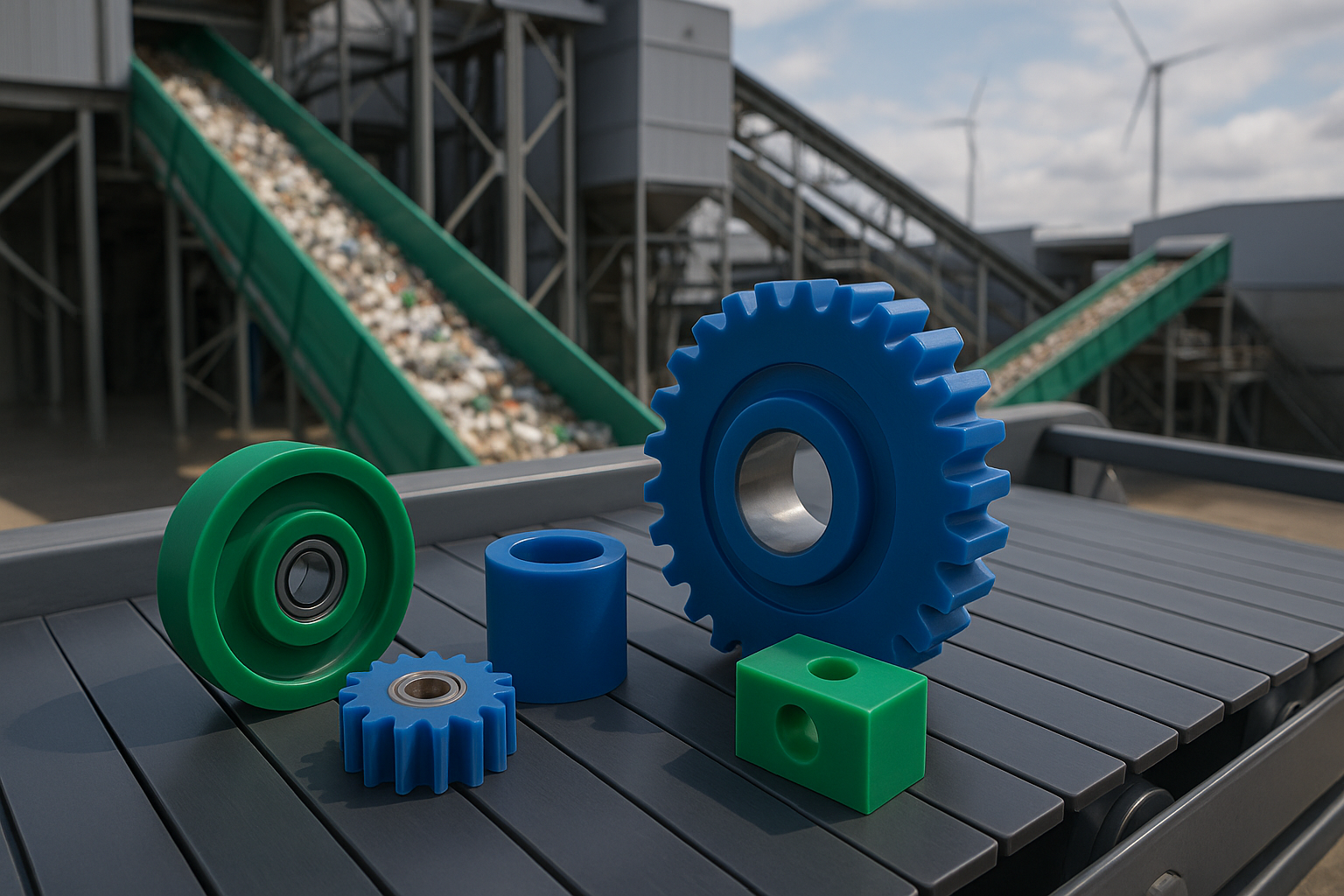

MC Nylon, a high-performance engineering plastic, is increasingly adopted as a replacement for metals and conventional plastics.

Performance advantages: lightweight, high wear resistance, low friction, and excellent chemical stability.

Applications:

Automotive and EV components (gears, bushings, bearings)

Industrial machinery (pulleys, chain wheels, guide rails)

Food-processing equipment (conveyor parts, rollers)

Environmental benefits:

Reduces reliance on metals and lowers manufacturing energy use

Extends component life, cutting replacement waste

Fully recyclable for secondary applications

Waste Management and the Circular Economy

Waste reduction is one of the most pressing issues for modern industries. The circular economy redefines waste as a resource—materials are recovered, reused, and reintegrated into production.

MC Nylon supports this model through:

Recycling: End-of-life gears, bushings, and pulleys can be shredded, remelted, and reprocessed into rods, sheets, or new components.

Cross-industry reuse: Worn MC Nylon parts from food machinery can be processed and reused in automotive or general machinery.

Closed-loop supply chains: Enterprises can establish take-back systems with suppliers to ensure MC Nylon components are collected and reintroduced into production.

Case Example:

A food-processing factory that adopted MC Nylon conveyor parts improved durability and introduced a recycling program. The result: 40% lower maintenance costs and a steady supply of secondary material for non-critical components. This demonstrates how waste management can create measurable economic and environmental value.

Implementation Strategies

Transitioning to sustainable materials like MC Nylon comes with initial hurdles—higher upfront investment, technical requirements, and underdeveloped recycling systems.

Practical steps include:

Leveraging government incentives and subsidies

Building partnerships across the supply chain for recycling networks

Using material innovation to cut lifecycle costs, balancing initial investments with long-term savings

Future Outlook

As industries move from compliance-driven sustainability to competitive sustainability, materials like MC Nylon will play a central role. With its recyclability, durability, and adaptability, MC Nylon aligns perfectly with the principles of lightweight design and circular manufacturing.

Conclusion

Sustainability is not just about compliance—it is about practical problem-solving. By combining waste management and circular economy principles with the adoption of MC Nylon, industries can reduce costs, extend product life, and minimize environmental impact.

The future of manufacturing belongs to companies that adopt durable, recyclable, and efficient materials. MC Nylon is one of the solutions leading that shift.

TAG:

Related News

How to Choose Sliding Parts: On-Site Differences Between PA6 and POM