Eco-Consciousness and the Role of MC Nylon

2025-09-01

Introduction

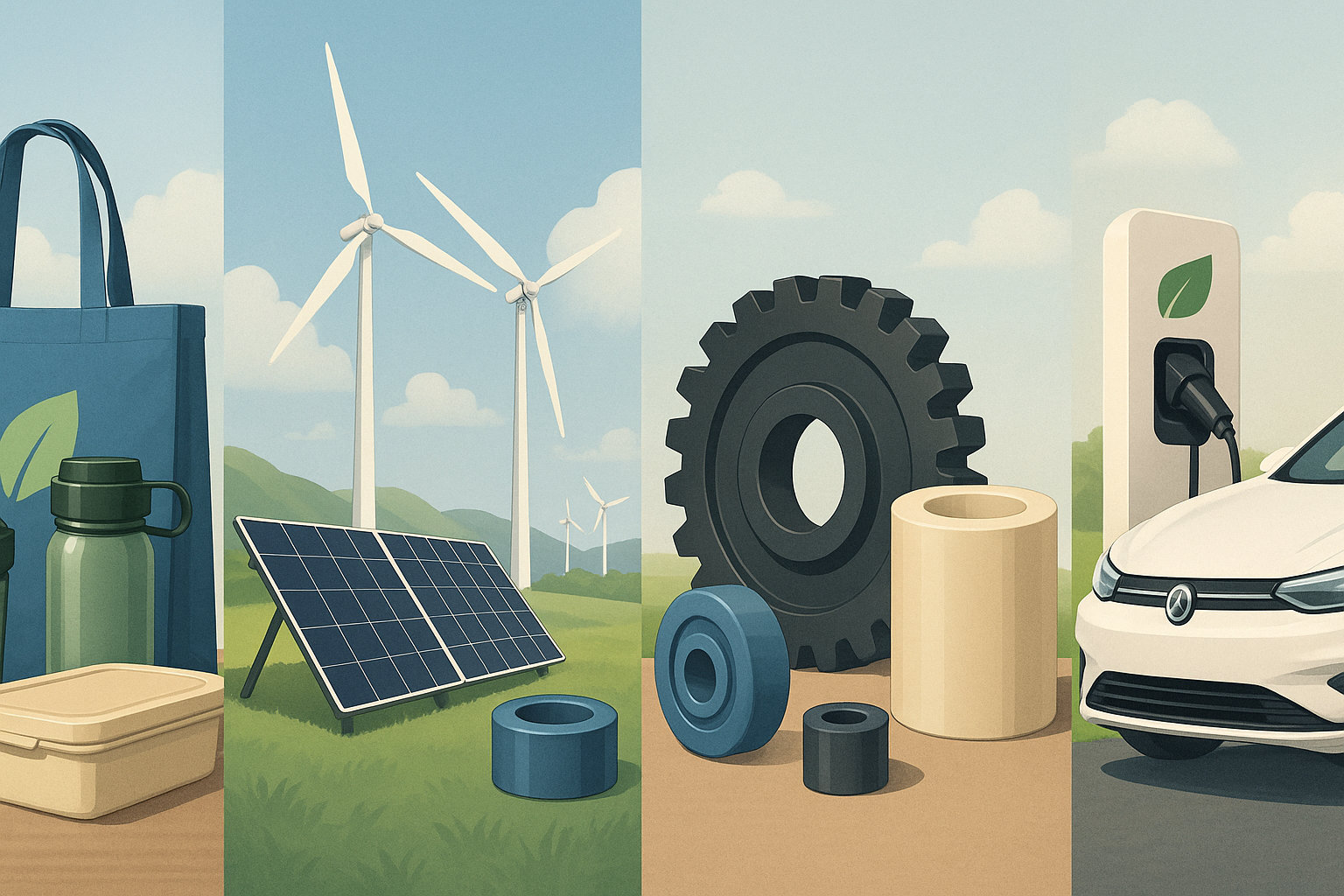

The rise of eco-consciousness is reshaping industries worldwide. Beyond renewable energy and sustainable packaging, material innovation is becoming equally critical. MC Nylon (Monomer Casting Nylon), a type of green engineering plastic, is replacing traditional metals and plastics across multiple sectors, offering both environmental and performance advantages.

Environmental Pressures and Industry Needs

Resource depletion, high energy consumption, and carbon emissions are driving companies to seek more efficient solutions. In industries such as automotive, electric vehicles, and heavy machinery, the demand for lightweight, durable, and recyclable materials is stronger than ever.

Key Trends in Sustainable Development

Recyclable & Biodegradable Packaging – Reducing single-use plastic waste.

Renewable Energy – Wider adoption of solar and wind power.

Eco-Friendly Textiles – Organic cotton and recycled fibers replacing conventional materials.

Green Engineering Plastics – Materials like MC Nylon reduce weight, replace metals, and extend product lifespan, making them a practical solution for sustainability.

The Advantages and Applications of MC Nylon

Performance Features

High strength and toughness

Excellent wear resistance and self-lubrication

Lightweight and corrosion-resistant

Good insulation properties

Component Applications

Nylon gears

Nylon bearings

Nylon pulleys

Nylon bushings

Industry Applications

Automotive & EVs – Lightweight components reduce energy consumption.

Industrial Machinery & Mining – Durable and wear-resistant parts lower maintenance costs.

Aerospace – Lightweight nylon parts help improve fuel efficiency.

Environmental Value

Metal replacement reduces emissions from mining and smelting.

Extended lifespan means fewer replacements and less waste.

Recyclable in certain forms, supporting circular economy practices.

Technology and Case Studies

Automotive/EVs: MC Nylon gears and bushings replace metal parts, lowering weight and improving efficiency.

Industrial Machinery: Bearings and pulleys made from MC Nylon last longer and reduce lubrication needs.

Aerospace: Lightweight nylon components contribute to lower fuel consumption and reduced carbon output.

Consumer and Market Drivers

Consumers increasingly value durability and sustainability. Brands using MC Nylon components not only enhance product performance but also strengthen their green brand image, gaining a competitive edge in the marketplace.

Conclusion and Outlook

While MC Nylon is not a biodegradable material, it is a green engineering plastic that contributes to sustainability through lightweight design, energy efficiency, and recyclability. As recycling systems improve, MC Nylon is expected to play a larger role in industries such as automotive, electric vehicles, industrial equipment, and aerospace.

TAG:

Related News

The Ultimate Guide to MC Nylon Sheets: Specifications, Performance, and Purchasing Advice