Why Does MC Nylon Warp – and How to Prevent It

2025-08-16

Introduction

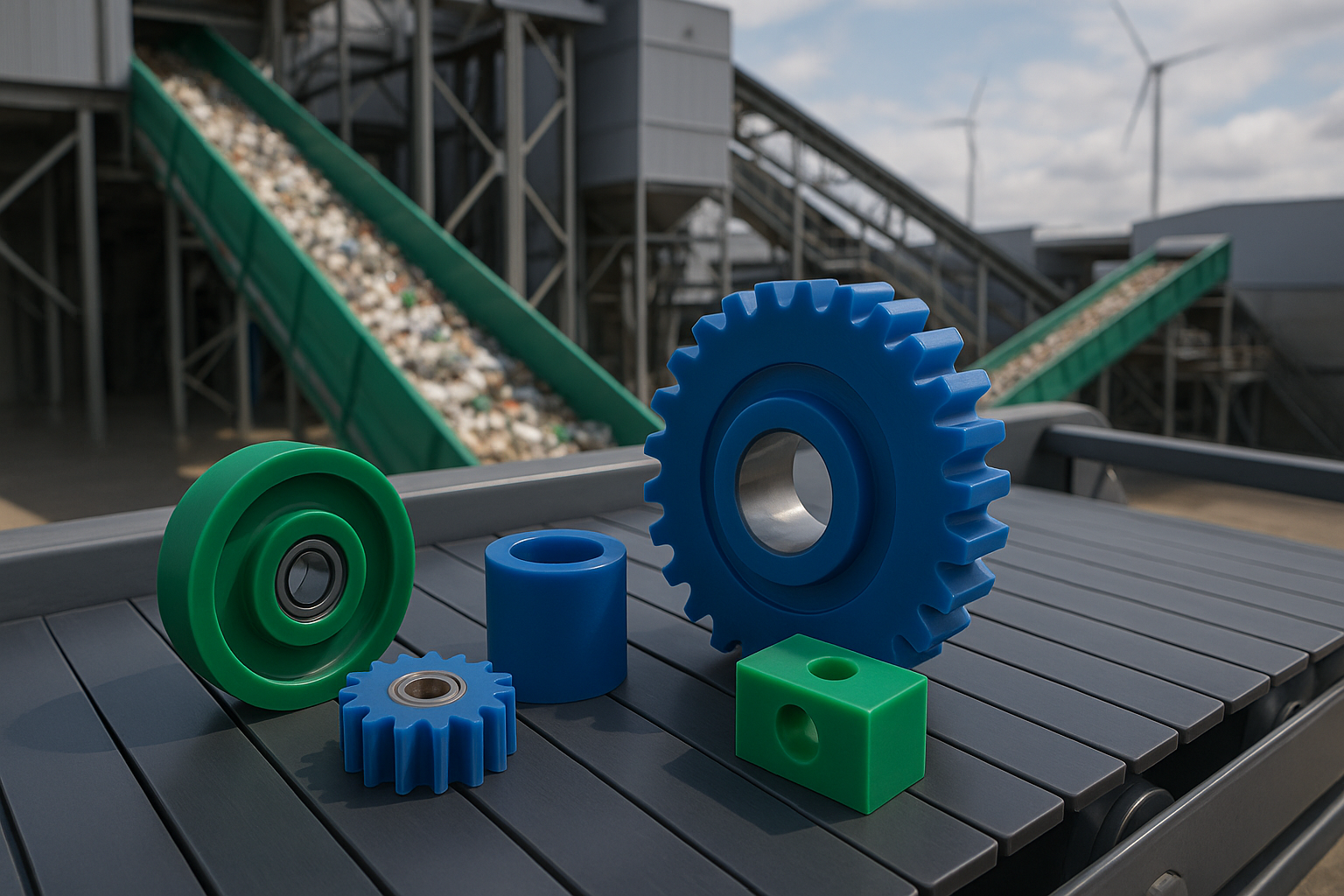

MC Nylon (monomer cast nylon) is renowned for its high strength, lightweight nature, and toughness, ideal for gears, rollers, pulleys, and wear-resistant components. However, warping can cause precision loss or fit failures, surprising even seasoned users. This article examines the causes of MC Nylon warping and offers actionable solutions to maintain shape and performance.

Core Reason: Nylon Absorbs Moisture

MC Nylon is hygroscopic, absorbing moisture from air or environments, with absorption rates of 1.5-3%, up to 7-9% at saturation, taking weeks (MatWeb, 2024). This leads to:

- Uneven expansion, with outer surfaces absorbing faster than the core.

- Internal stresses causing bending, twisting, or warping.

- Dimensional changes affecting precision and fits.

This is a natural environmental response, not a flaw.

Related Reading: How to Choose the Right Engineering Plastic

Other Common Causes of Warping

- Uneven Cooling After Casting or Machining

Faster cooling on one side causes uneven contraction (1-3%), distorting shapes, especially in large/thick parts. - Internal Stress from Machining

High-speed or aggressive machining introduces stresses, leading to warping hours or days later. - Improper Storage

Storing near heat sources or fluctuating humidity (e.g., open doors) causes uneven moisture absorption and deformation. - Thermal Expansion

MC Nylon’s thermal expansion coefficient (80-100×10⁻⁶/°C) is higher than metals (e.g., steel 10-12×10⁻⁶/°C), exacerbating warping (Engineering Toolbox, 2025). - Chemical Exposure

Strong acids (e.g., sulfuric acid) or alkalis may degrade the material, indirectly causing warping.

Related Reading: Common Mistakes in Engineering Plastics Processing

How to Prevent Warping

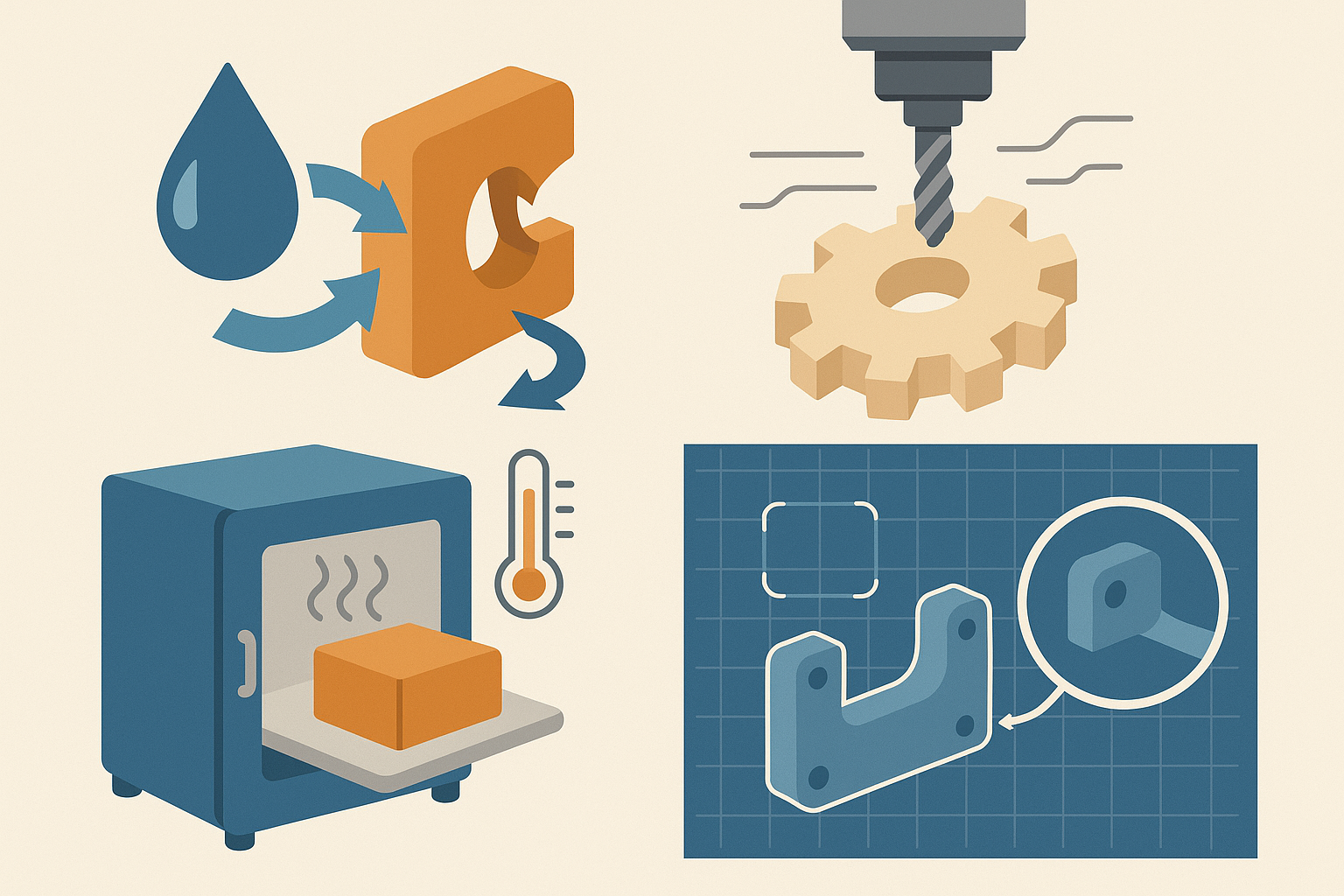

1. Dry the Material Before Machining

Moisture-absorbed material worsens warping during machining.

- Dry at 80-90°C (176-194°F) for 12-24 hours in an oven.

- Store immediately in sealed bags to prevent re-absorption.

- Tip: Follow Plastics International (2024) for optimal drying.

2. Let Parts “Relax” After Machining

Allow stress dissipation post-machining.

- Rest parts for 24-48 hours or anneal at 80-100°C for 2-4 hours for enhanced stability.

- For precision parts, rough-machine, then finish-machine the next day.

3. Store in Stable, Dry Conditions

- Seal parts in plastic bags or airtight containers, keeping humidity below 50%.

- Avoid stacking to prevent bending under weight.

- Use foam or flat supports to maintain shape.

4. Design with Material Properties in Mind

Account for moisture and thermal expansion:

- Use slots (width increased by 0.5-1 mm) instead of tight holes for movement.

- Add fillets (radius 1-2 mm) to reduce stress concentration.

- Minimize wall thickness (≥3 mm) for even moisture flow.

Sustainability: Environmental Considerations

Use recycled MC Nylon, chemically recycled to caprolactam, to reduce carbon footprint and support sustainable design.

Conclusion

MC Nylon warps due to its hygroscopic nature, thermal expansion, and machining stresses. By drying, annealing, storing properly, and designing smartly, you can achieve stable, durable, precise parts. Apply these tips to ensure top performance!

Call to Action

Share your MC Nylon experiences or questions in the comments! Contact us for a free MC Nylon Design Guide. Subscribe for more tips!

References

- MatWeb, “MC Nylon Material Data Sheet”, 2024, https://matweb.com/search/DataSheet.aspx?MatGUID=8d78f3cfcb6f49d595896ce6ce6a2ef1.

- Engineering Toolbox, “Linear Thermal Expansion Coefficients”, 2025, https://www.engineeringtoolbox.com/linear-expansion-coefficients-d_95.html.

- Plastics International, “Machining Guidelines for MC Nylon”, 2024, https://www.plasticsintl.com/machining-guidelines.

TAG:

Related News

Eco-Consciousness and the Role of MC Nylon