How to Extend the Life of MC Nylon Components

2025-08-16

Introduction

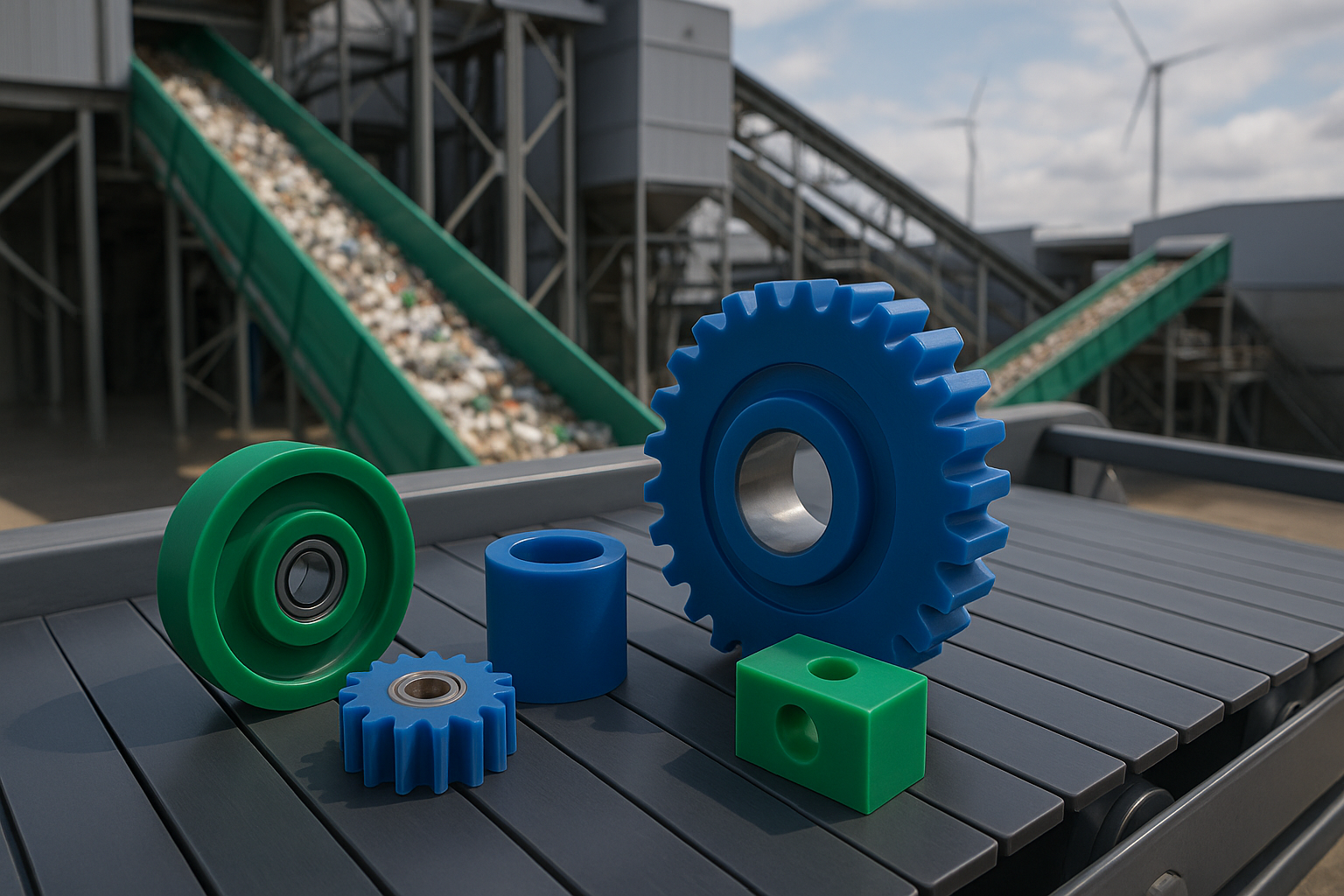

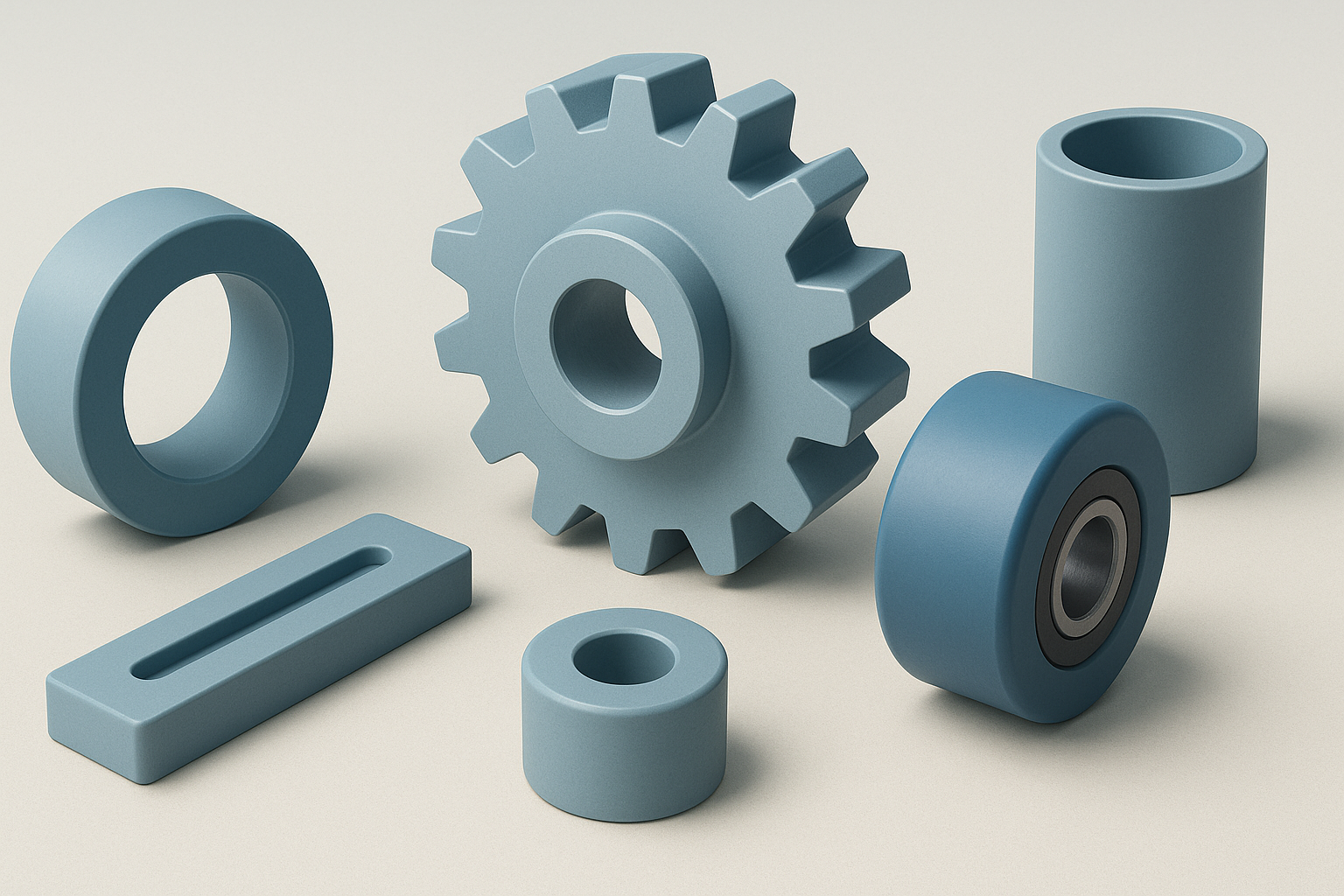

MC nylon, known for its high strength, wear resistance, and low noise, is widely used in gears, rollers, sliders, and bushings. However, improper use or maintenance can lead to premature failure, such as wear, cracking, or functional loss from dimensional expansion. This article shares proven methods, based on industry experience and materials science insights (August 2025), to extend MC nylon component lifespan, minimizing downtime and costs.

1. Control Temperature to Protect Performance

MC nylon softens at high temperatures, with strength declining at 80°C (176°F). High friction, poor ventilation, or heat sources can accelerate wear.

What to Do:

- Optimize Design: Avoid sharp corners and thin walls to reduce stress and heat buildup.

- Reduce Friction: Use slower speeds or effective lubricants in high-friction applications.

- Heat-Resistant Variants: Choose heat-resistant MC nylon (e.g., with high-temperature fillers) for up to 126°C continuous operation.

Expert Tip: Per Advances in Materials Science and Engineering (2024), heat-resistant MC nylon extends life by 20% in high-temperature settings.

2. Manage Humidity to Maintain Precision

MC nylon absorbs water in humid environments, causing expansion and reduced hardness. Absorption is typically 1.5-3%, up to 7-9% at saturation, taking weeks.

What to Do:

- Dry Storage: Store components in a dry, stable environment before installation.

- Environmental Adaptation: Machine high-precision parts after stabilization in the working environment.

- Water-Resistant Variants: Use water-resistant MC nylon (e.g., oil-filled) in wet or submerged conditions.

Data Insight: Oil-filled MC nylon reduces dimensional changes by ~15% in high humidity (Journal of Polymer Science, 2023).

3. Keep Components Clean and Lubricated

MC nylon has self-lubricating properties, but dust or abrasive particles accelerate wear. Prolonged metal contact can also degrade performance.

What to Do:

- Regular Cleaning: Clean surfaces in dusty environments to prevent particle embedding.

- Proper Lubrication: Use silicone-based or synthetic grease in high-load/friction areas, avoiding oil-based lubricants.

- Self-Lubricating Variants: Oil-filled MC nylon reduces maintenance and extends lifespan.

Industry Example: A manufacturer extended gear life by 30% using oil-filled MC nylon and regular lubrication.

4. Optimize Design for Strength

MC nylon excels in impact resistance but can deform under heavy or uneven loads if poorly designed.

What to Do:

- Rounded Corners: Use 1-2 mm fillet radii to reduce stress concentrations.

- Add Support: Incorporate ribs or thicker sections (wall thickness ≥3 mm) in load-bearing areas.

- Avoid Thin Walls: Ensure adequate thickness to prevent bending or cracking.

Design Tip: Per Shigley's Mechanical Engineering Design (2024), fillet design reduces stress concentrations by ~25%.

5. Protect Against UV and Chemical Exposure

Sunlight and chemicals like strong acids (e.g., sulfuric acid) or oxidizers can make MC nylon brittle or degrade it.

What to Do:

- Shield from Sunlight: Use covers or shields for outdoor components.

- Check Chemical Compatibility: Consult compatibility charts, avoiding strong acids.

- Protective Measures: Apply epoxy or polyurethane coatings for UV or chemical exposure.

Reference Insight: Per Industrial Plastics Application Guide (2023), UV-protective coatings extend outdoor lifespan by 40%.

6. Ensure Proper Installation and Mounting

Improper installation, like over-tightened bolts or uneven pressure, can cause cracking or deformation.

What to Do:

- Distribute Loads Evenly: Use broad mounting surfaces or washers.

- Avoid Over-Tightening: Apply bolt torque of 5-15 Nm, adjusted for part size.

- Proper Shaft Installation: Ensure correct press fits or keying to avoid wobbling.

Practical Tip: A torque wrench reduces installation-related stress damage.

7. Sustainability: Environmental Considerations

Recycled MC nylon, via chemical recycling to caprolactam, reduces carbon footprint, supporting circular economy and sustainable design.

Conclusion

MC nylon’s longevity depends on design, maintenance, and environmental control. By managing temperature, humidity, lubrication, design, and UV/chemical exposure, you can extend component life, reduce costs, and enhance reliability.

Call to Action

Inspect your MC nylon components and optimize maintenance! Share experiences or contact us for a free MC Nylon Maintenance Guide. Subscribe for more expert content!

References

- Advances in Materials Science and Engineering, 2024, https://onlinelibrary.wiley.com/toc/5928/2024, June 2024.

- Journal of Polymer Science, 2023, https://onlinelibrary.wiley.com/journal/10974628, October 2023.

- Shigley's Mechanical Engineering Design, 2024, https://www.mheducation.com/highered/product/shigley-s-mechanical-engineering-design-nisbett-budynas/M9781260407648.html, March 2024.

- Industrial Plastics Application Guide, 2023, https://www.professionalplastics.com/professionalplastics/content/MGC-Design-Guide.pdf, December 2023.

TAG:

Related News

Eco-Consciousness and the Role of MC Nylon