Can You Machine MC Nylon Like Metal? Not Exactly — Here’s How

2025-08-16

Introduction

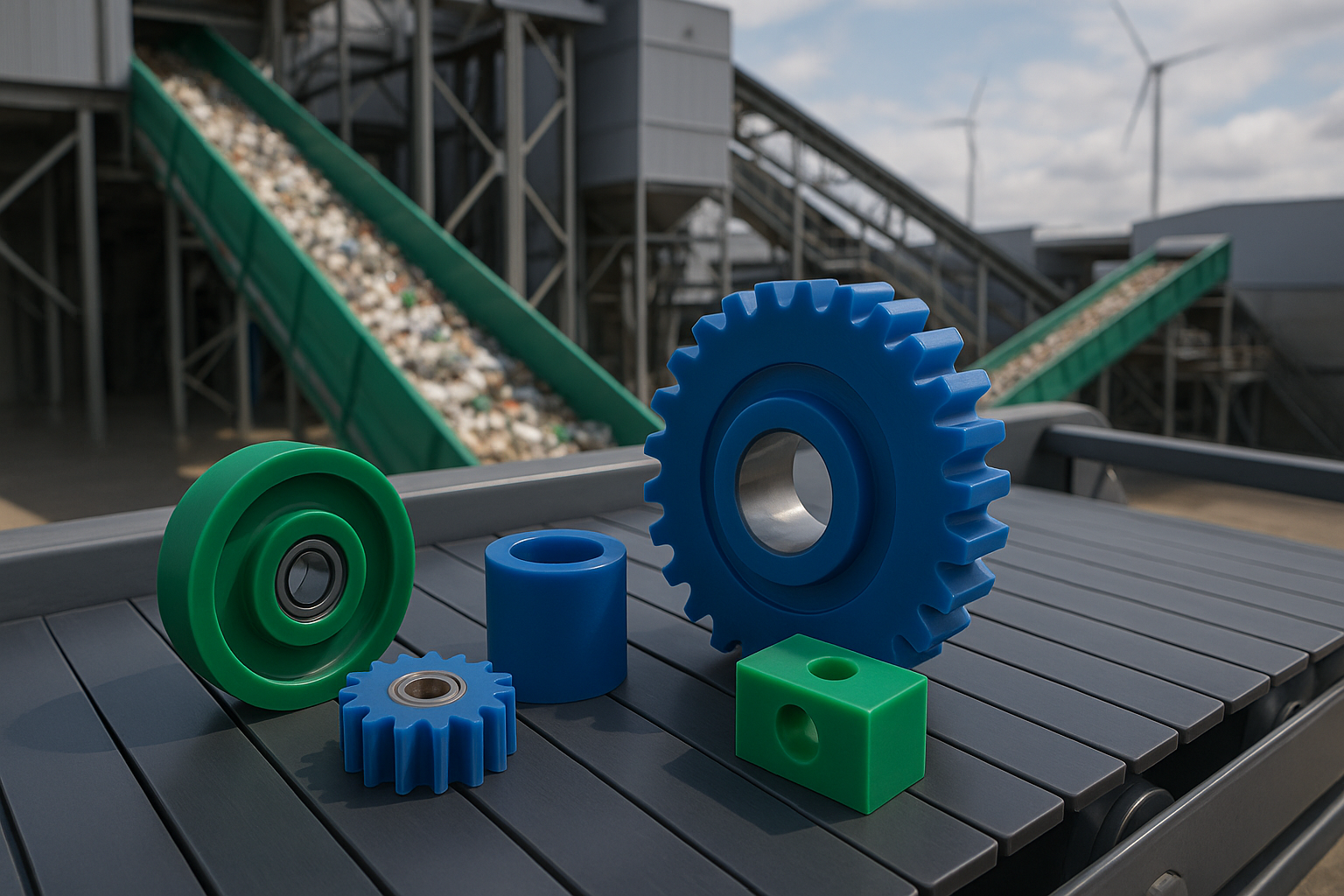

MC Nylon (monomer cast nylon) is a robust, durable engineering plastic used in gears, bushings, rollers, and wear pads. Its machining behavior differs significantly from metal. Treating it like steel or aluminum can cause rough surfaces, warping, or melted edges, leading to issues like gear wear or bushing seizure. This article explores MC Nylon’s properties and provides expert techniques for high-quality machined parts.

1. Heat Is Your Biggest Enemy

MC Nylon softens at 100-120°C (212-248°F), far below metal. Friction during machining can cause deformation or melted edges.

Solutions:

- Use sharp tools for clean cuts, minimizing friction heat.

- Reduce spindle speed (e.g., 500-1000 RPM for turning, adjust for size).

- Increase feed rate (0.1-0.3 mm/rev) to reduce friction time.

- Use water-based coolant or compressed air to cool and clear chips, avoiding oil-based coolants that may contaminate MC Nylon.

Pro Tip: Per Plastics International (2024), water-based coolant or compressed air significantly reduces heat buildup.

2. Chip Control Is Critical

MC Nylon produces long, stringy chips that wrap around tools or clog machinery, causing heat, tool wear, and dimensional errors.

Solutions:

- Use tools with chip breakers or manually clear chips between passes.

- Employ peck drilling, pausing every 5-10 mm to clear chips, especially for deep holes.

- For turning, use higher feed rates (0.1-0.3 mm/rev) for thicker, breakable chips.

3. Avoid Over-Clamping

MC Nylon compresses under pressure. Over-tightening a vise or chuck distorts parts, potentially preventing full recovery.

Solutions:

- Use soft jaws or plastic/rubber pads, keeping clamping force at 0.5-2 MPa.

- Distribute clamping force over a larger area.

- Machine close to final size, then lightly re-clamp (<0.5 MPa) for finish passes.

4. Temperature and Moisture Affect Dimensional Stability

MC Nylon expands/contracts with moisture (7-9% at saturation, taking weeks) and temperature changes, unlike fixed metal dimensions.

Solutions:

- Acclimate material in the workshop for 1-2 days to match service humidity.

- Use looser tolerances (e.g., ±0.3-0.8 mm for 50-200 mm parts), especially for mating parts.

- Store in a dry, shaded area to minimize moisture and thermal effects.

Reference: Per Curbell Plastics (2025), moisture absorption requires special attention.

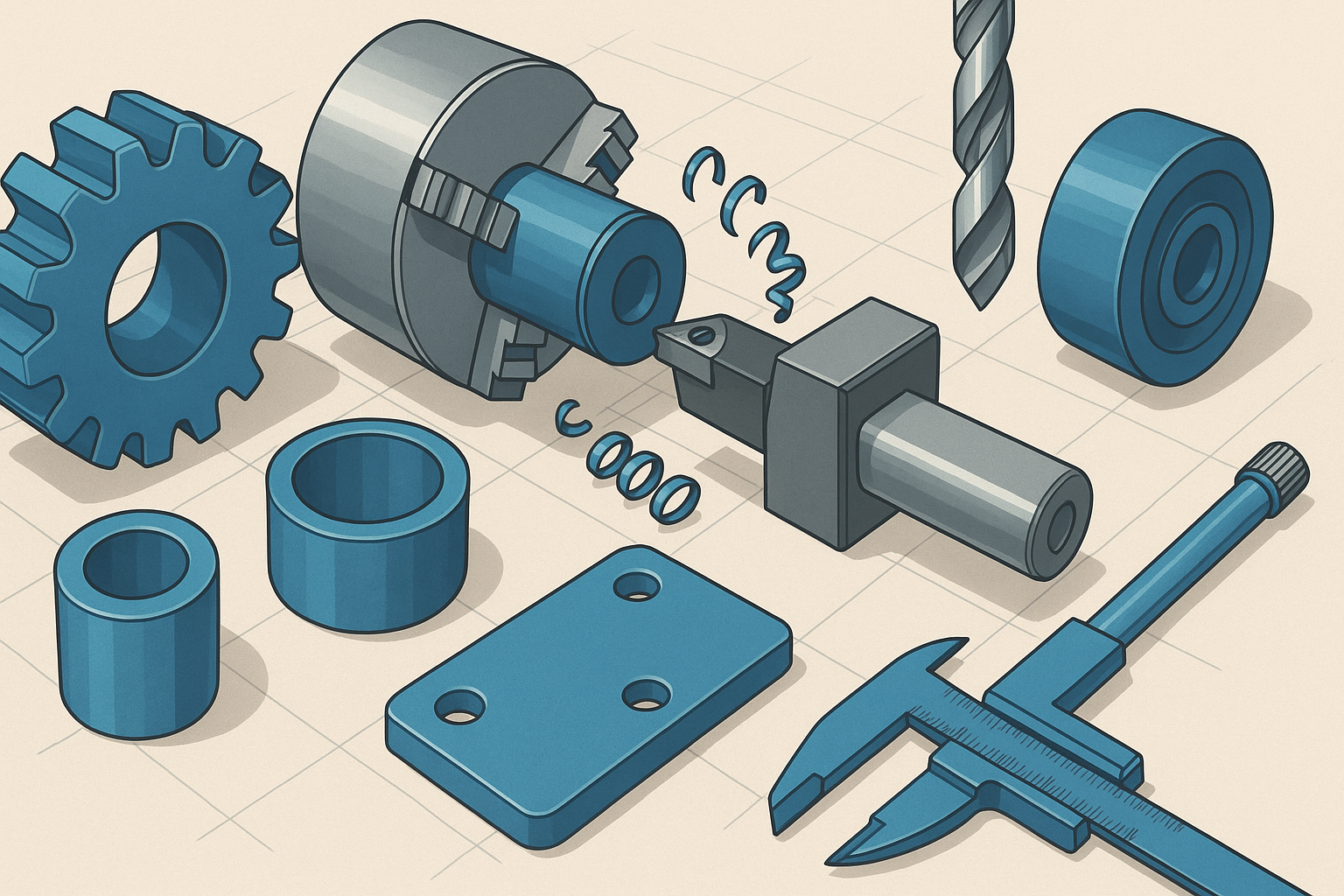

5. Optimal Tooling Choices

- Cutting Tools: Carbide tools excel; sharp high-speed steel (HSS) also effective.

- Drills: Neutral or negative rake twist drills, using step-drilling to reduce chip wrapping.

- Turning Inserts: Polished inserts for plastics or aluminum, with sharp edges.

- Sawing: Coarse-tooth band saw (4-6 TPI), 500-800 RPM, steady feed pressure.

Suggested Link: Engineering Plastics Machining Guide.

6. Post-Machining Stabilization

Post-machining, MC Nylon requires stress relief to stabilize shape, especially for precision parts.

Best Practices:

- Rest parts overnight at room temperature after heavy material removal.

- For precision parts, rough-machine, then finish-machine the next day.

- Anneal at 80-100°C for 2-4 hours to release stresses and prevent deformation.

7. Chemical Resistance

MC Nylon has limited resistance to strong acids (e.g., sulfuric acid) or alkalis. Avoid oil-based coolants during machining to prevent contamination that may degrade performance.

8. Sustainability: Environmental Considerations

Choose recyclable MC Nylon to reduce waste. Though recycling is complex, using recycled MC Nylon lowers resource use and carbon footprint, supporting eco-friendly manufacturing.

Conclusion

MC Nylon is highly machinable but requires attention to its low heat tolerance, flexibility, and chip control. By managing heat, clamping, and environmental factors, you can produce clean, precise, durable parts that outperform metals in many applications.

Call to Action

Optimize your MC Nylon machining! Share experiences or contact us for a free MC Nylon Machining Guide. Subscribe for more expert content.

References

- Plastics International, “Machining Guidelines for MC Nylon”, 2024, https://www.plasticsintl.com/machining-guidelines.

- Curbell Plastics, “Moisture Absorption in Nylon”, 2025, https://www.curbellplastics.com/en/technical-resources/technical-articles/moisture-absorption-nylon.

TAG:

Related News

Eco-Consciousness and the Role of MC Nylon