Designing with MC Nylon: Essential Tolerance Guidelines

2025-08-18

Introduction

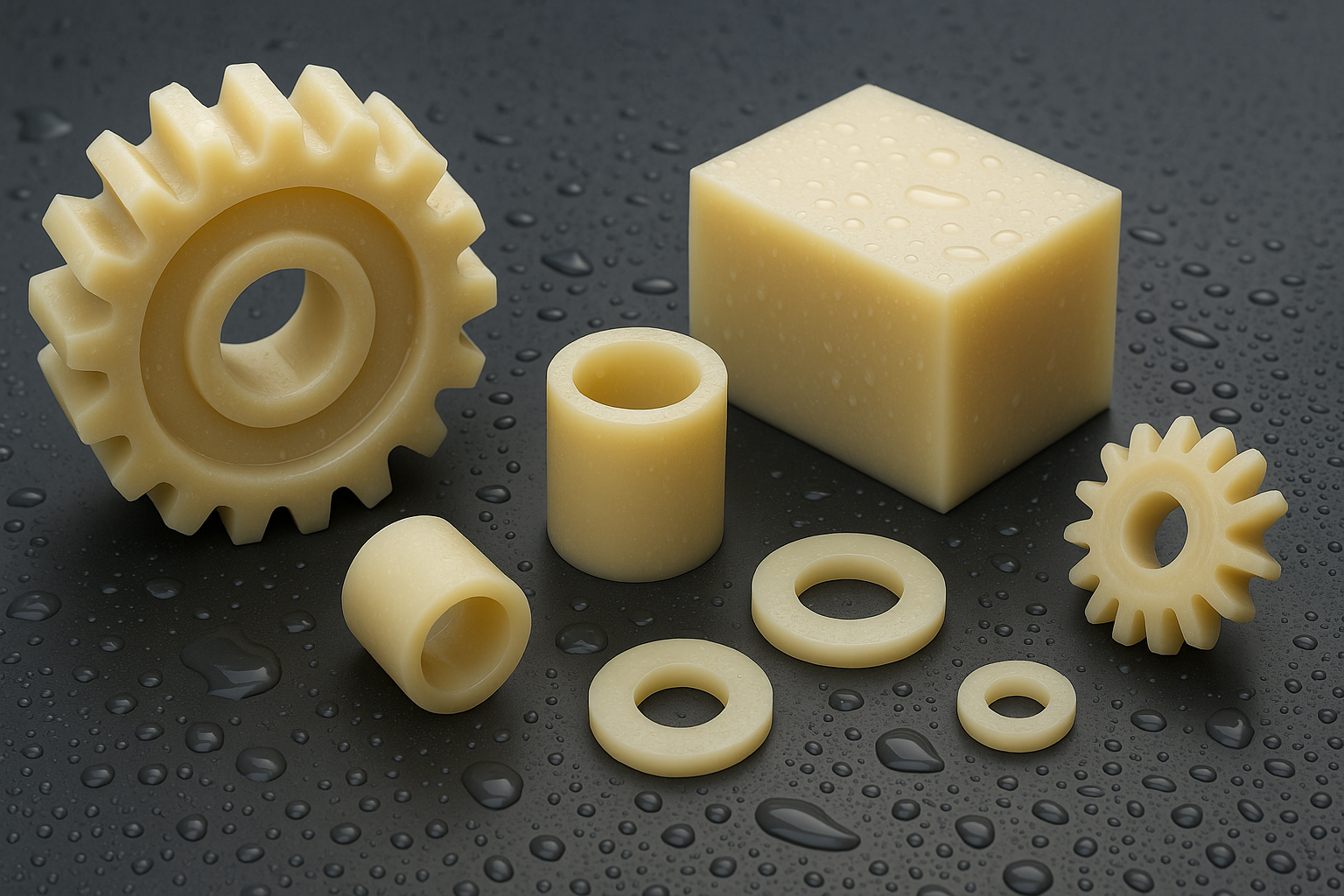

MC Nylon is a high-performance engineering plastic valued for its lightweight, durable, and self-lubricating properties, ideal for mechanical components. Unlike metal, it changes dimensions due to humidity, temperature, and load, risking failure like seizing fits or functional loss from expansion. This guide provides tolerance guidelines to ensure reliable MC Nylon parts.

1. MC Nylon’s Dynamic Nature: A Feature, Not a Flaw

MC Nylon, a semi-crystalline plastic, blends metal-like rigidity with plastic flexibility. Key dimensional factors include:

- Moisture: Absorbs water, causing 1.5%-2% expansion (up to 7%-9% at saturation, taking weeks depending on environment).

- Temperature: Higher thermal expansion than metals.

- Time and Load: Creep causes gradual deformation under sustained force.

These traits enable vibration reduction, shock absorption, and quiet operation but require careful tolerance design.

Reference: Per MatWeb Material Database, MC Nylon’s moisture absorption (1.5%-2%, up to 7%-9% at saturation) impacts dimensional stability.

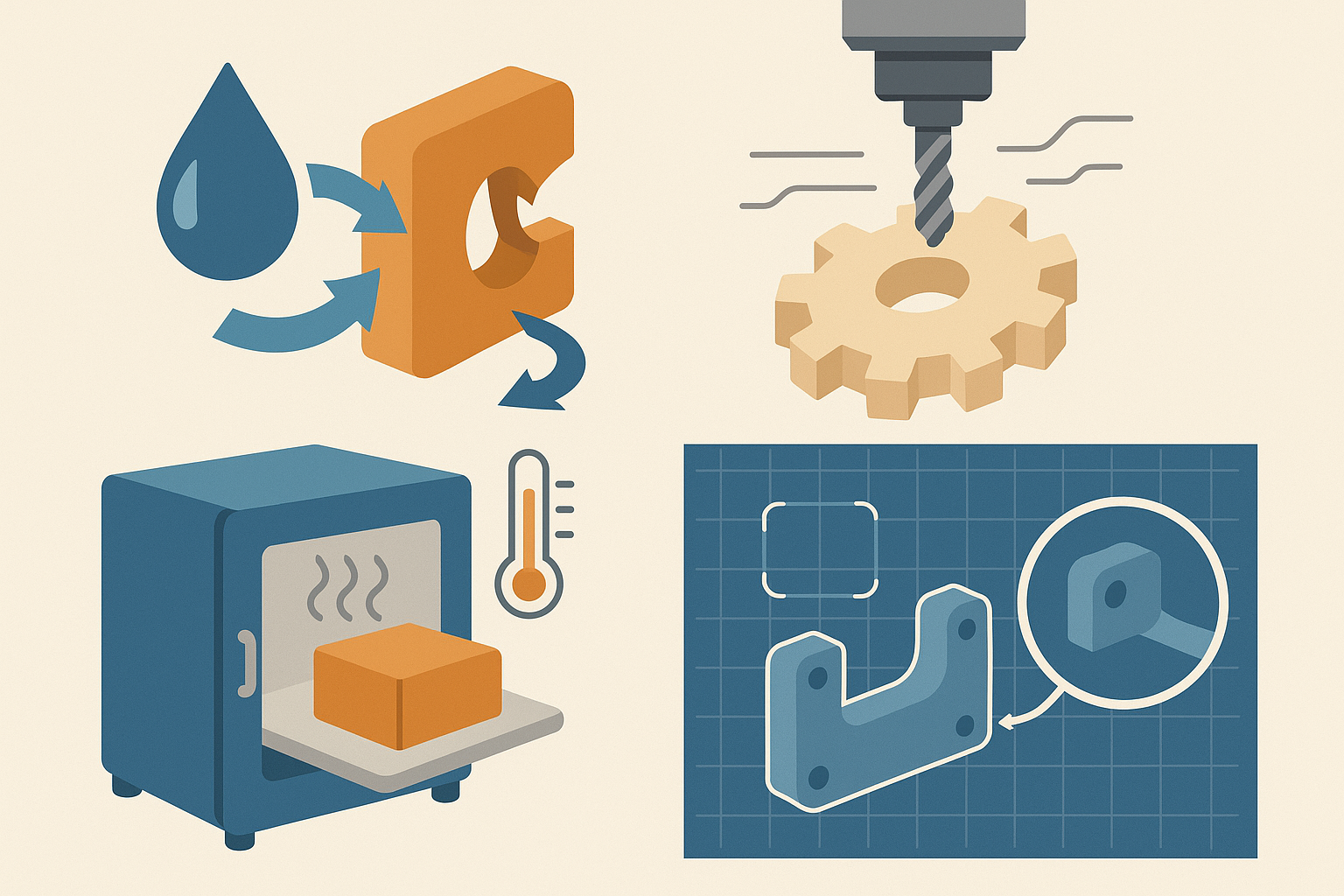

2. Post-Casting Shrinkage: The First Tolerance Challenge

MC Nylon is cast from liquid monomer, shrinking 1.5%-2.5% during polymerization, varying with geometry and cooling conditions. Complex parts may need higher margins, affecting near-net shape dimensions.

Design Tips:

- Allow post-machining for precision.

- Collaborate with suppliers on mold design to account for shrinkage.

- Anneal after machining to release stresses and enhance stability.

3. Moisture Expansion: The Hidden Dimension Shifter

Humidity is the greatest long-term tolerance challenge. Dry conditions maintain stability, but humid or submerged environments cause expansion (e.g., 100 mm part to 102 mm, up to 7%-9% at saturation).

Solutions:

- Pre-condition Parts: Expose to service humidity before machining to mimic real-world conditions.

- Design Clearances: Add space in fits, guides, and bores for expansion.

- Avoid Press Fits: These may loosen or seize due to expansion.

Example: A water pump seal failed in humid conditions due to overlooked expansion. Pre-conditioning and a 0.5 mm clearance resolved it.

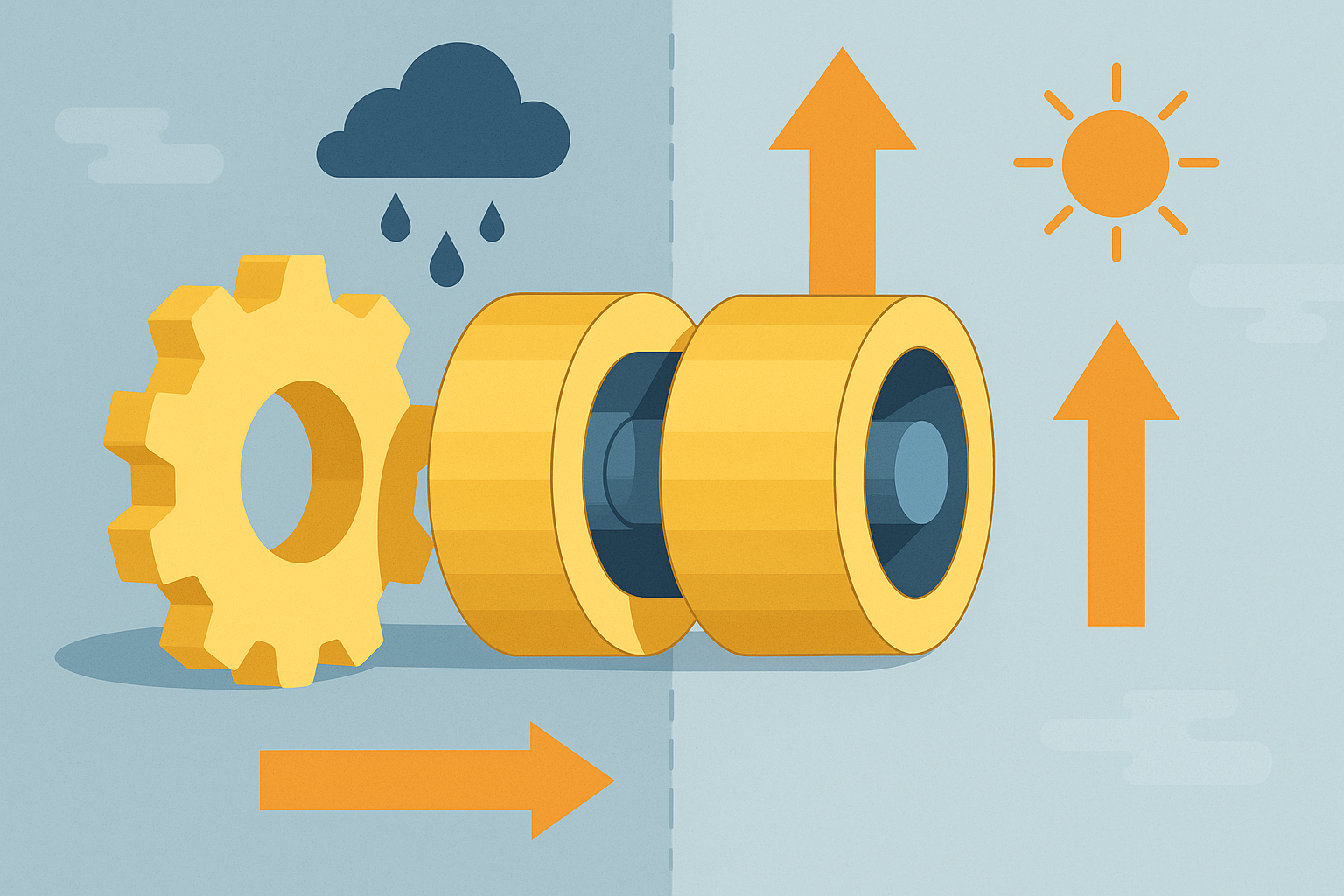

4. Thermal Expansion: Small but Significant

MC Nylon’s thermal expansion coefficient is ~9 times that of steel (80-100 x 10⁻⁶/°C). Misalignment occurs in high-temperature machinery. It performs stably below 100-120°C; above this, design cautiously.

Design Tips:

- Avoid tight stacking in high-heat zones.

- Provide buffers for differential expansion with metals.

Reference: Per Engineering Toolbox, MC Nylon’s coefficient is 80-100 x 10⁻⁶/°C vs. steel’s 10-12 x 10⁻⁶/°C.

5. Tolerance Guidelines: Quick Reference

Recommended tolerances for MC Nylon parts (typical applications):

Dimension Range (mm) | Recommended Tolerance (mm) |

0 – 50 | ±0.1 to ±0.3 |

50 – 200 | ±0.3 to ±0.8 |

200 – 500 | ±0.8 to ±1.5 |

> 500 | Case-by-case, include expansion margins |

Note: Widen tolerances in high-humidity or wide-temperature settings. Post-machining annealing enhances stability, allowing tighter tolerances.

6. Practical Design Strategies

Best practices include:

- Oversized Holes and Slots: Avoid tight bores for movement.

- Bushings or Sleeves: Use metal/composite bushings in critical fits.

- Flexible Design: Prioritize function under dynamic changes over long-term stability.

- Chemical Resistance: In corrosive environments, MC Nylon’s limited resistance to strong acids/alkalis requires special formulations.

7. Sustainability: Environmental Considerations

MC Nylon is recyclable via chemical or mechanical methods, though complex. Recycled MC Nylon reduces resource use and carbon footprint, ideal for sustainable designs.

Conclusion: Design for Dynamics

MC Nylon’s dynamic behavior may challenge those used to metal precision, but its lightweight, durable, and self-lubricating properties excel in many applications. Understand and design for its behavior.

With clearances, pre-conditioning, and current data, you can create reliable MC Nylon parts. Work with the material, not against it!

Call to Action

Have you accounted for MC Nylon’s dynamic properties? Share experiences or contact us for a free MC Nylon design handbook: https://example.com/contact.

References

- MatWeb, “MC Nylon Material Data Sheet”, 2025, https://matweb.com/search/DataSheet.aspx?MatGUID=8d78f3cfcb6f49d595896ce6ce6a2ef1.

- Engineering Toolbox, “Linear Thermal Expansion Coefficients”, 2025, https://www.engineeringtoolbox.com/linear-expansion-coefficients-d_95.html.

TAG:

Related News

Unlocking the Secrets: Common Questions About Cast Nylon