Unveiling the Wonders of Cast Nylon: A Comprehensive Guide

2025-08-16

What is Cast Nylon?

Cast nylon, or nylon 6, is a type of polyamide that has captured the attention of manufacturers and engineers alike. It's made through a process called polymerization, where caprolactam is transformed into a solid form. This nifty creation boasts impressive strength and durability, making it a go-to material for many applications.

Why Choose Cast Nylon?

When it comes to selecting materials, cast nylon stands tall among its peers. Here are a few reasons why:

- Exceptional Strength:Cast nylon is renowned for its high tensile strength, which means it can withstand heavy loads without breaking a sweat.

- Wear Resistance: It's got a natural resistance to abrasion, making it perfect for applications that involve friction.

- Low Friction Coefficient: This material glides smoothly against other surfaces, reducing wear and tear in mechanical components.

- Versatility: Whether you're in the automotive, aerospace, or manufacturing industry, cast nylon can be molded into various shapes and sizes to meet your needs.

Applications Galore!

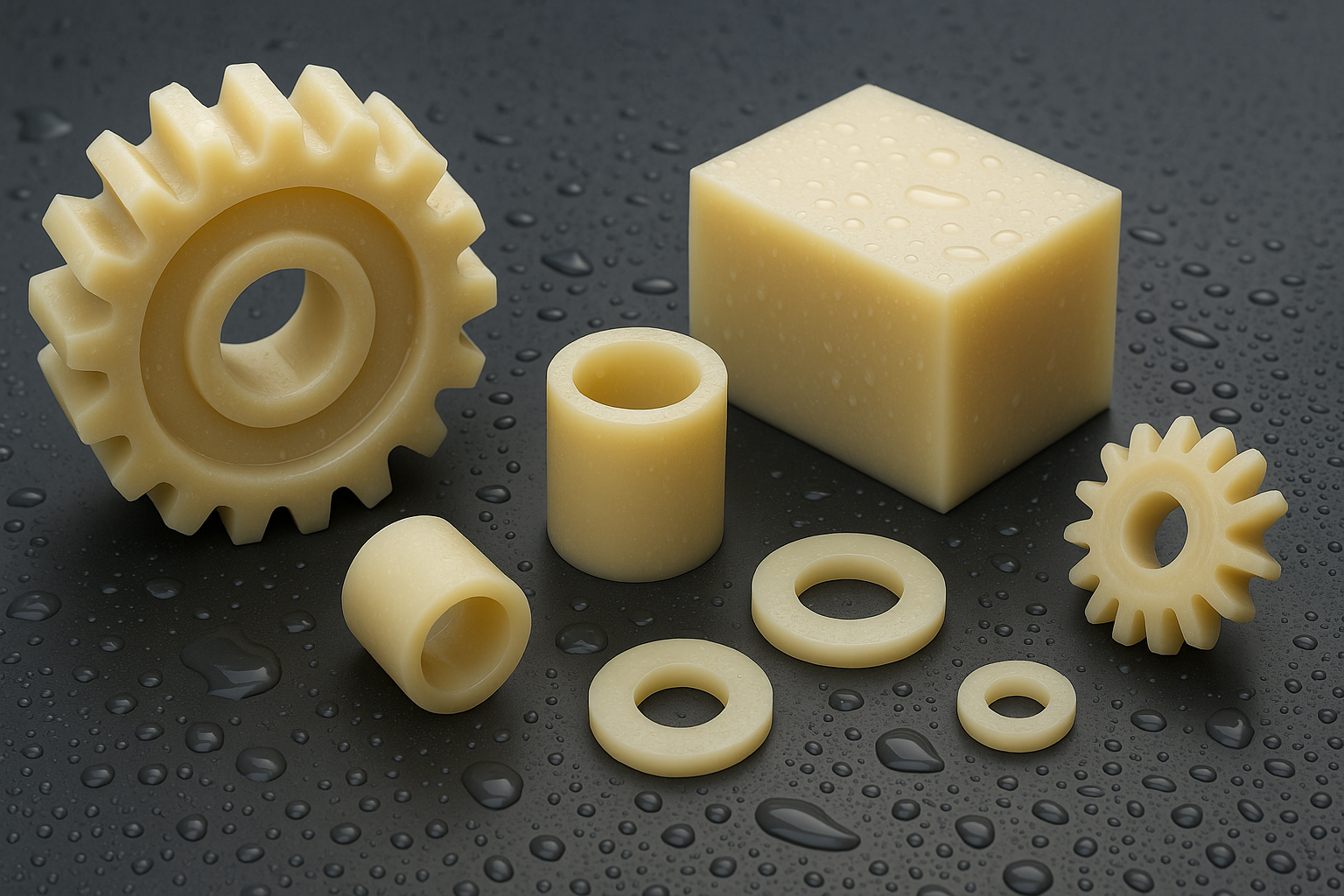

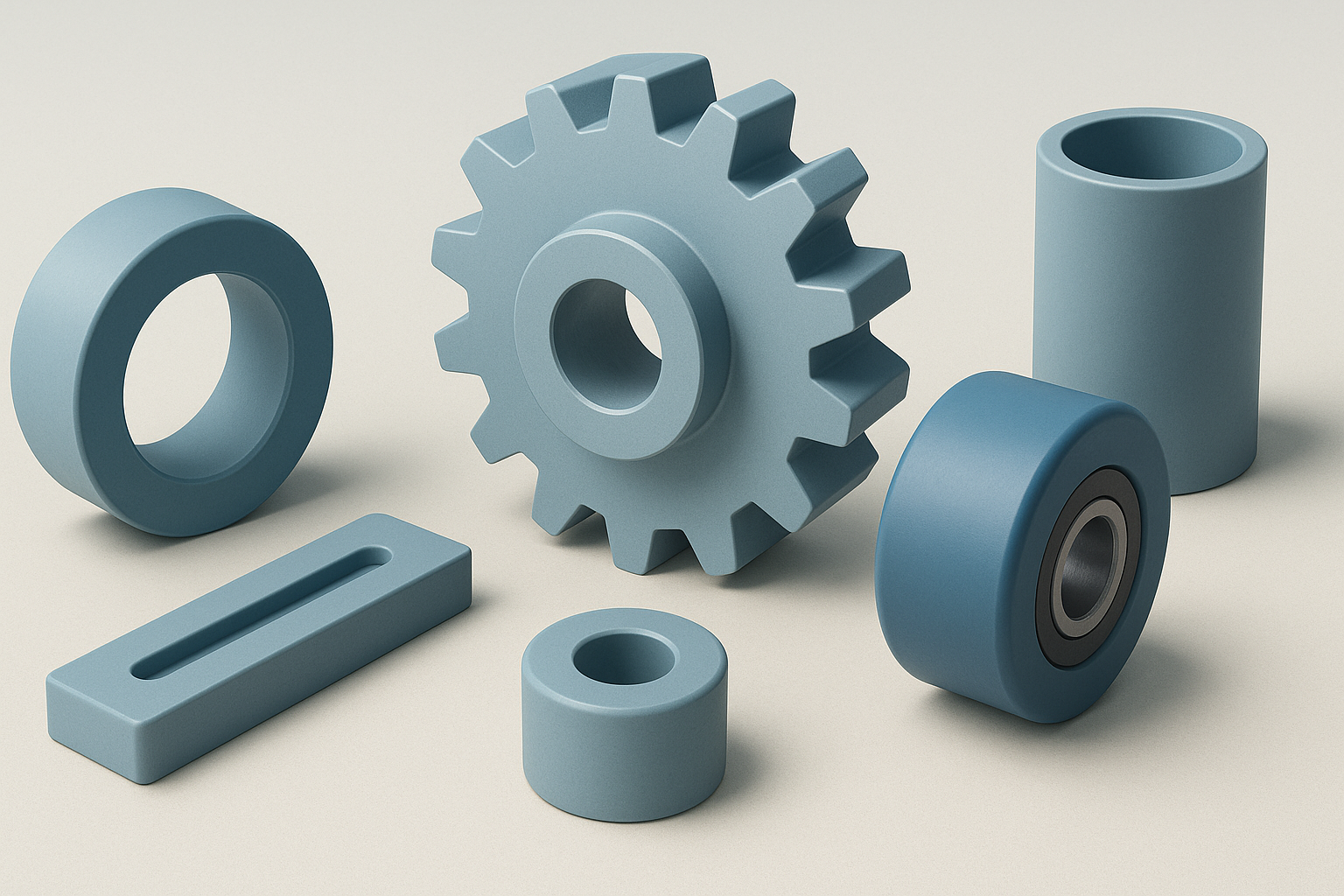

From gears to bushings, cast nylon is a superstar in many applications. Here's a quick rundown:

- Automotive Parts: It's used in the production of parts like timing belt pulleys and fuel system components.

- Aerospace:Cast nylon plays a crucial role in aircraft components due to its lightweight and durable nature.

- Industrial Machinery: Its wear resistance makes it ideal for conveyor systems and other machinery parts that undergo constant movement.

The Manufacturing Process

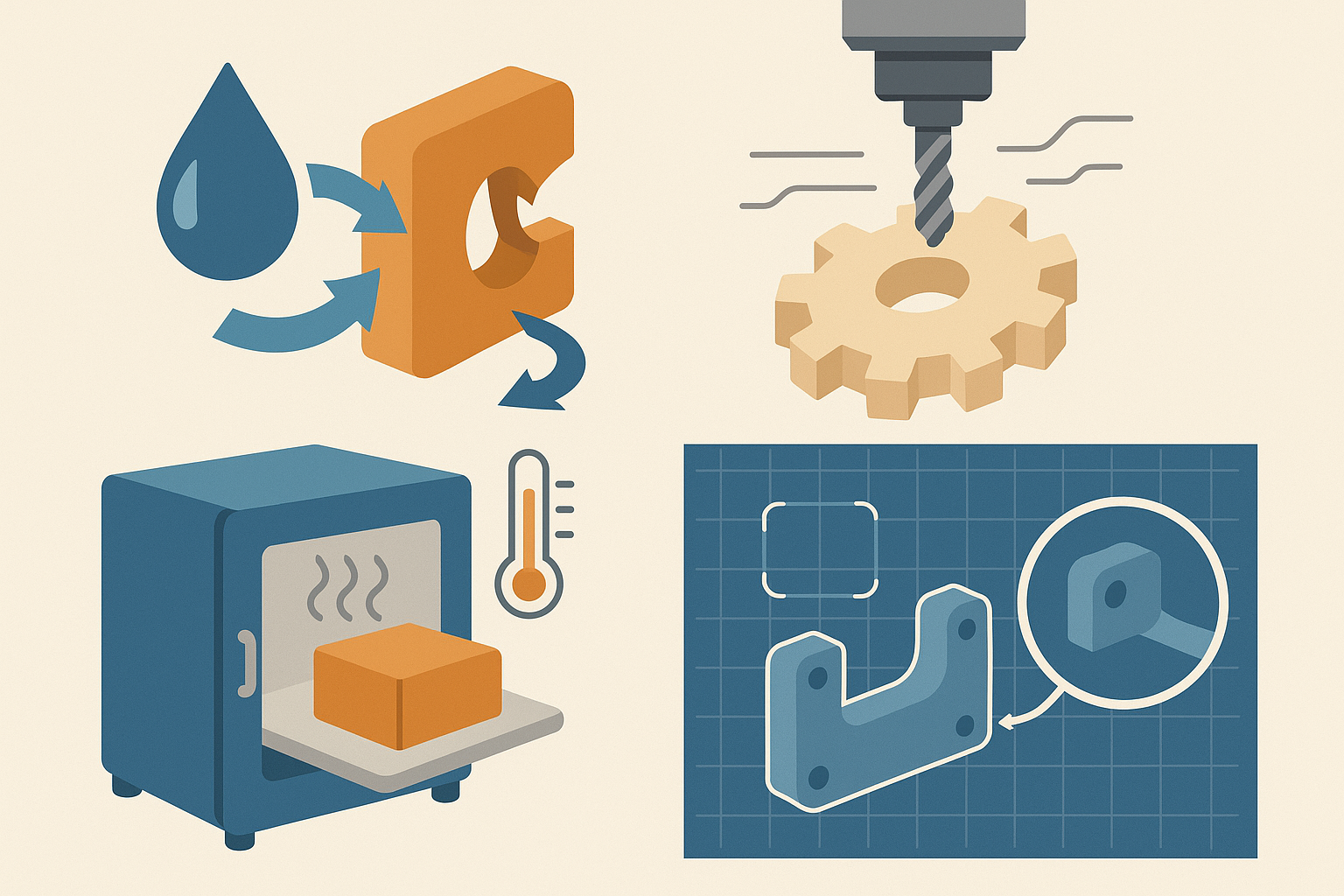

Now, let's get into how this marvelous material is made. The process involves:

- Polymerization: Caprolactam is heated, causing it to undergo a chemical reaction that forms long chains of nylon.

- Cooling: The molten nylon is then cooled and solidified into blocks, which can be further machined into the desired shapes.

- Finishing: Finally, the cast nylon can be treated or coated for additional properties like UV resistance or improved friction characteristics.

Benefits of Cast Nylon

So, why should you jump on the cast nylon bandwagon? Here's the scoop:

- Cost-Effective: Compared to metals and other engineering plastics, cast nylon offers a more budget-friendly option without compromising quality.

- Lightweight: Its low density means you can save on weight without sacrificing strength.

- Customizable: It's easily machinable, allowing for custom shapes and sizes to fit specific applications.

- Corrosion Resistance: Unlike metals, cast nylon doesn't rust, making it suitable for various environments including moist and corrosive settings.

Challenges to Consider

Of course, no material is without its drawbacks. Here are a few challenges associated with cast nylon:

- Moisture Absorption:Cast nylon can absorb water, which may affect its dimensions and mechanical properties.

- Temperature Sensitivity: High temperatures can lead to deformation, so it's vital to consider the operating environment.

- Limited UV Resistance: Prolonged exposure to sunlight can degrade its quality, so protective measures are often necessary.

Conclusion

In a nutshell, cast nylon is a fantastic material with a plethora of benefits and applications, making it an invaluable asset in various industries. Whether you're designing a new product or just looking to learn more about materials, cast nylon deserves a spot on your radar. With its strength, versatility, and cost-effectiveness, it's no wonder that it has become a favorite among engineers and manufacturers alike!

TAG:

Related News

The Hidden Role of Moisture in MC Nylon Performance