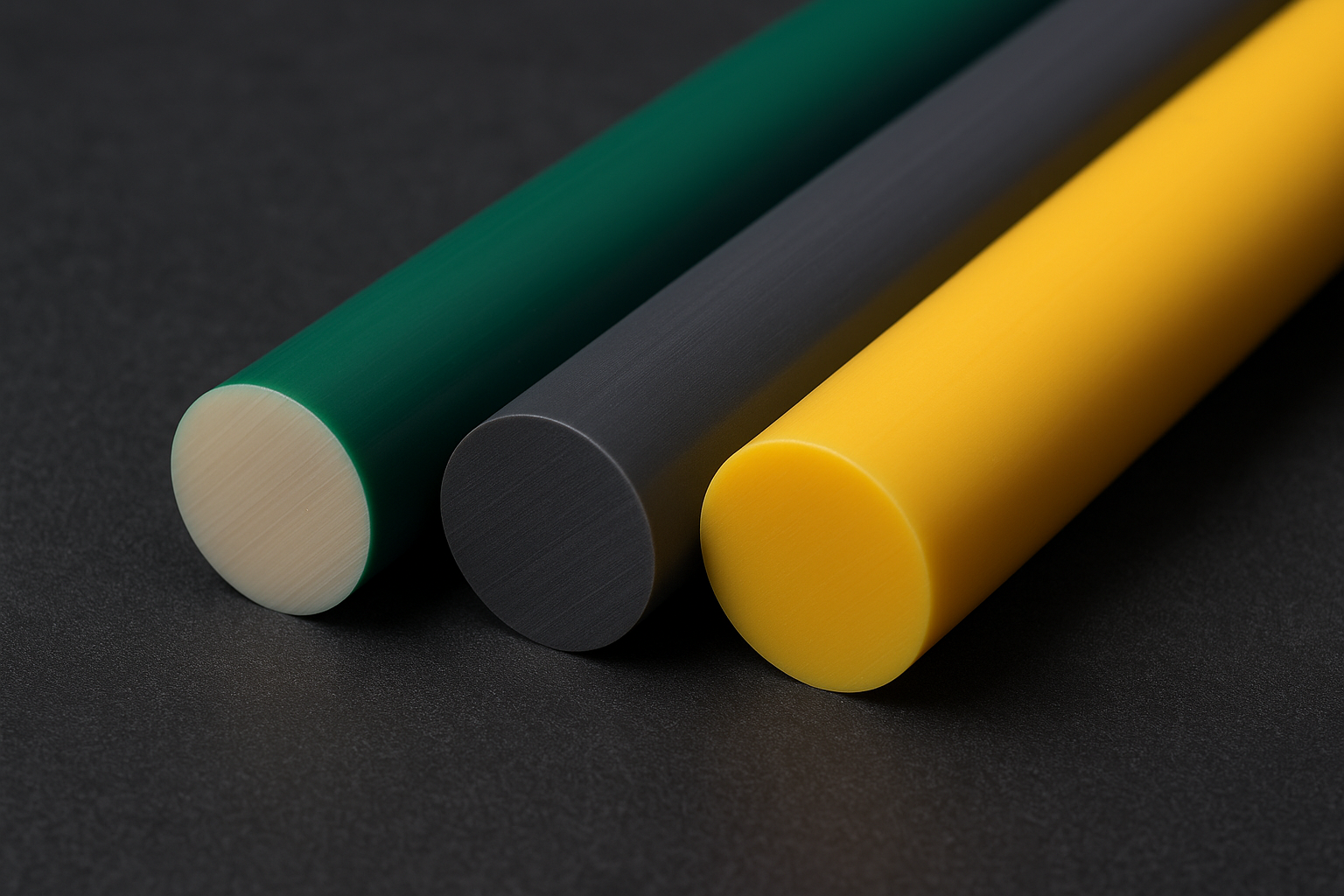

How to Choose the Right MC Nylon Grade: Standard, Oil-Filled, MoS2-Filled, and More

2025-08-16

Introduction

MC Nylon (Monomer Cast Nylon) is a versatile engineering plastic valued for its strength, low friction, and machinability in industrial applications. Choosing the right grade can enhance part longevity, reduce maintenance, and improve efficiency. With over 15 years of materials engineering experience, I’ve seen mismatched grades cause premature failures, like swelling in humid conditions or wear in high-friction setups. This guide details MC Nylon grades, backed by industry data and real-world cases, to help you make informed choices.

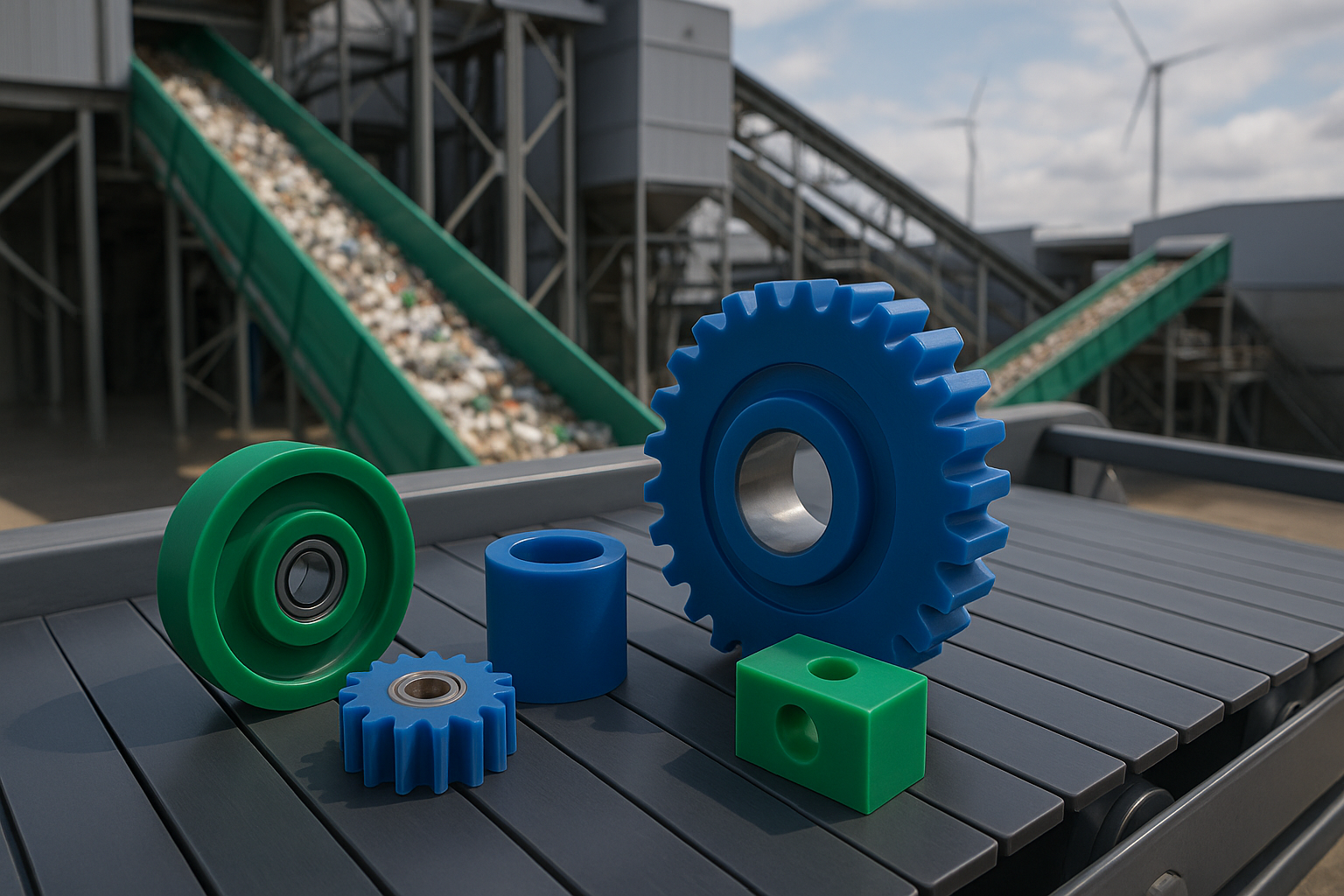

Standard MC Nylon (Unfilled/Natural)

Standard MC Nylon is the foundational grade without additives, ideal for cost-effective, general-purpose applications.

Best for:

- General-purpose parts: bushings, rollers, spacers, pulleys

- Dry environments with moderate loads

- Components needing basic strength and low friction

What it does well:

- High tensile strength (10,000-12,000 psi, ~69-83 MPa), lightweight

- Easy to machine with good self-lubricating properties

- Excellent impact resistance and fatigue endurance

Watch out for:

- High moisture absorption (7-9% in high humidity, 1-2% in dry conditions), causing dimensional swelling (Source: MatWeb, MC Nylon Data Sheet, 2024).

- Unsuitable for high-speed sliding or wet conditions due to swelling/stability issues.

- Limited resistance to strong acids (e.g., sulfuric acid) or alkalis, requiring special formulations.

In practice: Performs well in controlled indoor settings, like conveyor systems in manufacturing plants.

Oil-Filled MC Nylon (Lubricated Grade)

Oil-Filled MC Nylon incorporates lubricating oil during casting, providing embedded lubrication.

Best for:

- Sliding/rotating parts: chain guides, wear pads, gears, conveyor components

- Applications with impractical or infrequent external lubrication

- Low-friction, low-maintenance environments

What it does well:

- Friction coefficient ~25% lower than standard (0.1-0.3 vs. 0.3-0.5), PV limit ~10,000-15,000 psi·ft/min, extending wear life.

- Self-lubricating in dry conditions, quieter operation, lower energy use.

- Stable under moderate loads with good compressive strength.

Watch out for:

- Slightly lower tensile strength (8,000-10,000 psi, ~55-69 MPa).

- Higher cost, offset by reduced downtime.

- Limited resistance to strong acids/alkalis.

In practice: Extends service intervals in automotive bushings and mining equipment by reducing greasing needs.

MoS2-Filled MC Nylon (Molybdenum Disulfide Grade)

MoS2-Filled MC Nylon adds molybdenum disulfide for enhanced wear resistance and structural integrity.

Best for:

- High-load, high-friction parts: gears, sheaves, bearings

- Dry, high-stress environments

- Applications needing superior dimensional stability

What it does well:

- Increased stiffness, strength, and PV limit (~15,000-20,000 psi·ft/min) for high loads.

- Lower thermal expansion coefficient, reducing deformation.

- Enhanced wear resistance, with ~10-15% lower impact strength but suited for abrasive settings.

Watch out for:

- Increased brittleness, reducing impact resistance.

- Gray-black color, unsuitable for aesthetic applications.

- Limited resistance to strong acids/alkalis.

In practice: Outperforms standard nylon in heavy machinery gear assemblies by reducing wear rates.

Heat-Stabilized MC Nylon

Heat-Stabilized MC Nylon is modified to maintain performance in elevated temperatures.

Best for:

- Continuous heat environments (80-120°C/176-248°F): industrial ovens, heated rollers, engine compartments

- Thermal cycling or oxidative environments

- Structural parts needing long-term stability

What it does well:

- Maintains shape and properties up to 126°C (260°F) continuously, briefly up to 150°C, resisting thermal aging/cracking.

- Improved oxidative stability, preventing brittleness.

- Combines with other properties for hybrid applications.

Watch out for:

- Degradation above 130°C for extended periods.

- Slightly higher cost.

- Limited resistance to strong acids/alkalis.

In practice: Essential for maintaining dimensional accuracy in food processing ovens under heat stress.

Water-Resistant MC Nylon (Low Moisture Absorption Grade)

Water-Resistant MC Nylon minimizes water uptake, ideal for harsh environments.

Best for:

- Marine/aquatic parts: pump components, dock rollers, submerged equipment

- Humid or wet environments needing dimensional stability

- Moisture-prone applications

What it does well:

- Lower moisture absorption (3-5% vs. 7-9% for standard), reducing swelling.

- Good resistance to saltwater and weak acids, less maintenance.

- Retains mechanical properties in humidity.

Watch out for:

- May require custom orders, limited supplier availability.

- Lower strength than reinforced grades like MoS2-filled.

- Limited resistance to strong acids (e.g., sulfuric acid), requiring special formulations.

In practice: Prevents failures from moisture exposure in offshore platforms.

Sustainability: Environmental Considerations

MC Nylon can be recycled via chemical or mechanical methods, though the process is complex. Using recycled or bio-based MC Nylon reduces resource use and carbon footprint. Compared to metal production, MC Nylon’s lifecycle can be more environmentally friendly, especially in low-maintenance applications.

Choosing the Right Grade: Quick Guide

Match your needs with the best MC Nylon grade:

Need | Recommended MC Nylon Grade |

General purpose, dry use | Standard / Natural MC Nylon |

Sliding/rotating without grease | Oil-Filled MC Nylon |

High wear and load | MoS2-Filled (Moly) MC Nylon |

Constant heat | Heat-Stabilized MC Nylon |

Wet or humid environment | Low Moisture Absorption MC Nylon |

High heat + high load | Heat-Stabilized MoS2-Filled MC Nylon |

Conclusion

Selecting the right MC Nylon grade aligns material properties with application demands to maximize durability and efficiency. For complex needs like high heat and load, consider Heat-Stabilized MoS2-Filled MC Nylon. Always verify supplier stock and test prototypes to ensure performance.

Call to Action

Choose the right MC Nylon grade for your application! Contact us for a free MC Nylon selection consultation: https://example.com/contact. Subscribe for more materials guides!

References

- Mitsubishi Chemical Group, “Nylons as Engineering Plastics”, 2025, https://www.mcam.com/en/products/nylons.

- Emco Industrial Plastics, “Nylon Cast Oil Filled Type 6”, 2025, https://www.emcoplastics.com/nylon-cast-type-6-oil-filled/.

- Emco Industrial Plastics, “Nylon Cast MoS2 Filled Type 6”, 2025, https://www.emcoplastics.com/nylon-cast-type-6-mos2-filled/.

- Protolabs, “Types of Nylons Compared”, 2023, https://www.protolabs.com/resources/blog/types-of-nylon/.

TAG:

Related News

Eco-Consciousness and the Role of MC Nylon