Replacing Bronze, Brass, and Aluminum with MC Nylon: What Changes

2025-08-16

Introduction

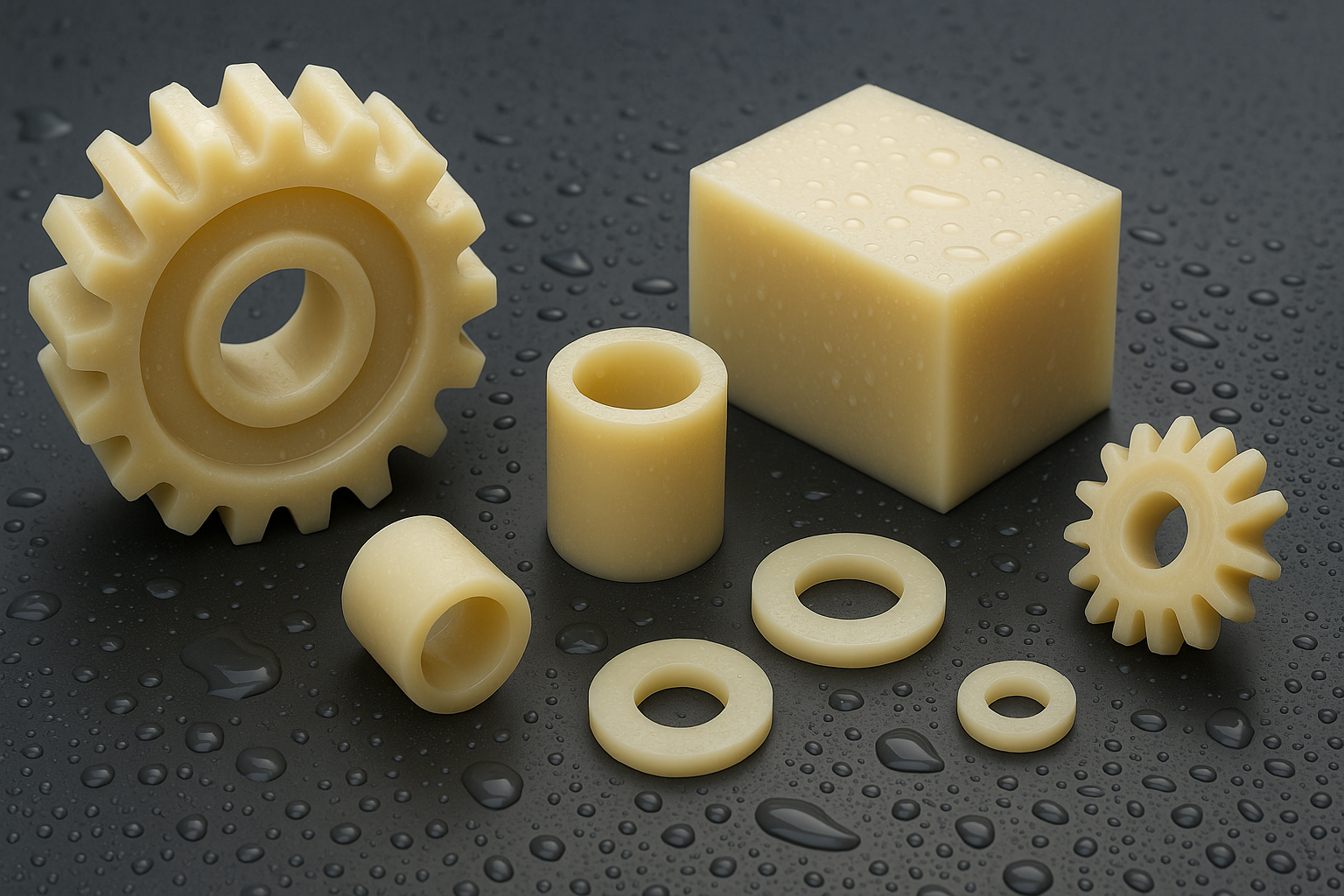

Replacing metals like bronze, brass, or aluminum with MC Nylon in industrial parts isn’t just about cutting weight or costs—it fundamentally changes how parts perform under stress, over time, and in real-world conditions. This article explores key changes and offers practical tips for a smooth transition.

Why Choose MC Nylon?

Companies opt for MC Nylon over metals for compelling reasons:

- Weight Reduction: MC Nylon weighs ~1/7.7th of bronze, 1/7th of steel, and 1/2.3th of aluminum.

- Self-Lubrication: Oil- or graphite-filled grades reduce lubrication needs (standard MC Nylon friction coefficient ~0.3-0.5, better than unlubricated metals).

- Lower Costs: Cost-effective for large/complex parts, lower than bronze/brass, comparable to aluminum but with efficient casting.

- Reduced Wear: Softer MC Nylon minimizes damage to mating components.

- Corrosion Resistance: No rust/oxidation, but limited resistance to strong acids (especially inorganic) or alkalis, requiring special formulations.

Note: Switching isn’t a simple “plug-and-play”; consider the following changes.

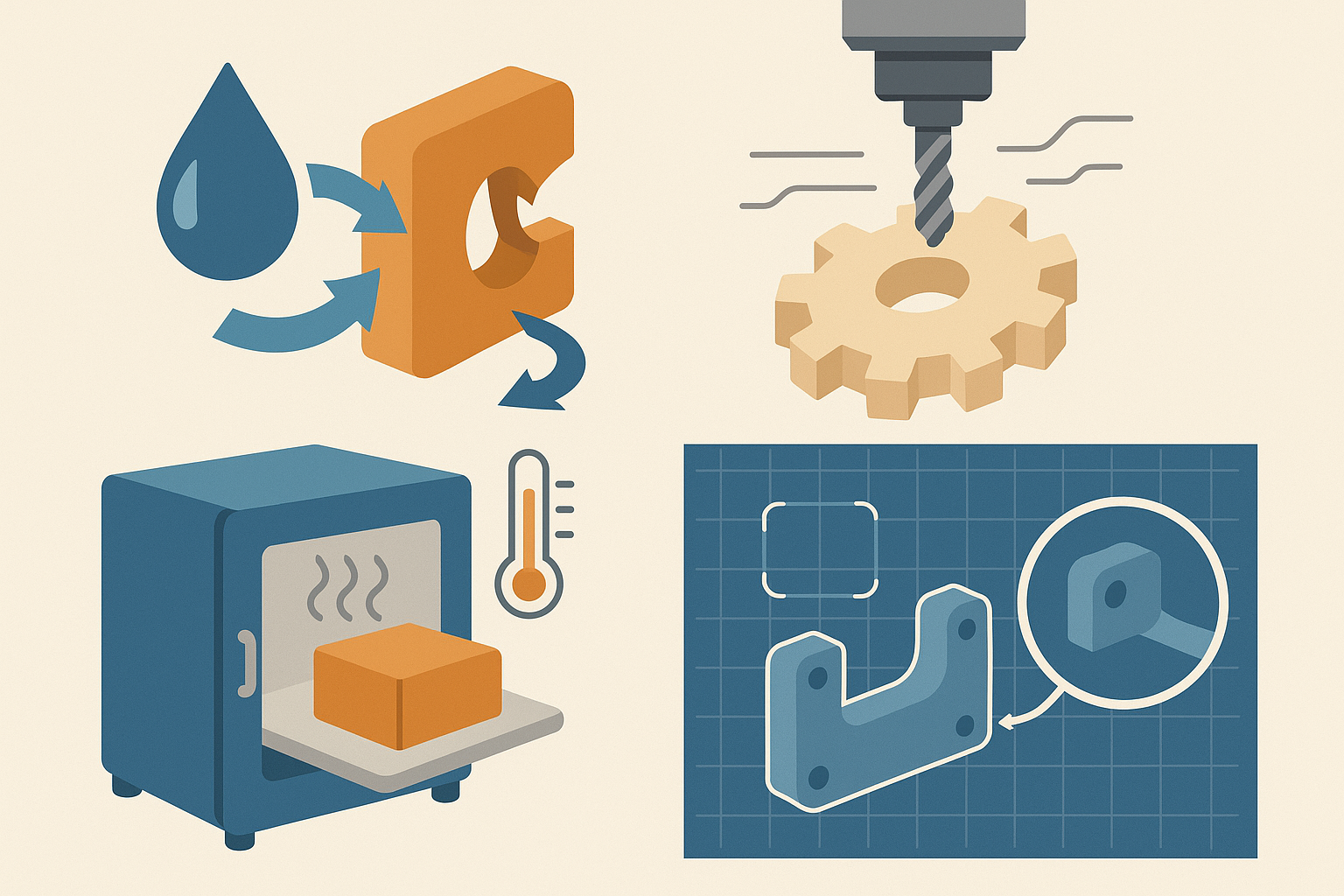

1. Dimensional Stability

Metals: Highly stable, minimally affected by environment.

MC Nylon: Prone to dimensional changes.

- Absorbs moisture, causing expansion (0.7%-1%, up to 2-3% in high humidity) (Source: MatWeb, MC Nylon Material Data Sheet, 2024).

- Higher thermal expansion coefficient than bronze or aluminum, more sensitive to temperature changes.

Design Tip:

- Incorporate larger clearances, avoid tight press fits.

- Pre-condition parts (e.g., soaking/drying) for critical dimensions.

2. Load Capacity and Stiffness

Metals: Rigid, minimal deformation.

MC Nylon: Strong but more flexible.

- Lower modulus of elasticity than bronze or aluminum, leading to deflection in thin/long parts (Source: Engineering Toolbox, Material Properties Comparison, 2025).

- Creep under long-term stress causes gradual deformation; avoid continuous high-load scenarios.

Design Tip:

- Use thicker cross-sections or ribbing to reduce bending.

- Avoid flat, unsupported surfaces in load-bearing roles.

3. Wear and Friction

MC Nylon excels in this area.

- Bronze/Brass: Slow wear but require lubrication, may scratch mating parts.

- MC Nylon: Naturally low-friction, especially oil-filled grades; standard MC Nylon friction coefficient ~0.3-0.5, better than unlubricated metals.

Bonus: MC Nylon reduces noise, ideal for replacing bushings/gears in noise-sensitive applications.

4. Heat Tolerance

- Bronze/Aluminum: Handle 400°C+ with ease.

- MC Nylon: Softens at 100-120°C, may deform under prolonged heat, but can briefly withstand 150°C (Source: Plastics International, MC Nylon Technical Specifications, 2024).

Design Tip:

- Monitor friction-induced heat in rotating parts.

- Use PA6G with heat stabilizers or external cooling/lubrication for high temperatures.

5. Machining and Assembly

MC Nylon is easy to machine but differs from metals.

- Requires sharp tools, slower speeds to prevent surface melting/smearing.

- Cannot be welded/soldered; use bolts, adhesives, or interference fits (accounting for moisture expansion).

- Annealing post-machining recommended to release internal stresses, preventing deformation.

Machining Tip: Follow guidelines (e.g., CNCMachinist.com, MC Nylon Machining Tips, 2025) to optimize.

6. Cost and Production Speed

- MC Nylon stock shapes are less expensive than bronze/brass, comparable to aluminum.

- Large parts (e.g., rollers/pulleys) are faster/cheaper to cast in MC Nylon than machine from metal.

- Near-net shape casting reduces machining time/waste.

7. Sustainability: Environmental Considerations

MC Nylon can be recycled via chemical/mechanical methods, though complex. Recycled or bio-based nylon reduces resource use and carbon footprint. Compared to metal production, MC Nylon can be more environmentally friendly in certain scenarios.

When Does Switching to MC Nylon Make Sense?

Ideal Applications:

- Bushings

- Wear pads

- Rollers

- Slide plates

- Low-to-medium load gears

- Conveyor components

Less Suitable Applications:

- High-temperature environments

- Thin parts under constant high loads

- Precision assemblies with tight tolerances/no expansion allowance

- Strong acid/alkali environments (require special formulations)

Conclusion

Switching to MC Nylon from bronze, brass, or aluminum is a shift in part behavior. Leveraging its strengths (lightweight, low maintenance, quieter, cost-effective) and addressing limitations (dimensional changes, heat sensitivity) ensures success.

Call to Action

Design with MC Nylon’s properties in mind, not as a metal replacement. Evaluate your parts today to unlock MC Nylon’s potential! Contact us for an MC Nylon design guide。

TAG:

Related News

The Hidden Role of Moisture in MC Nylon Performance