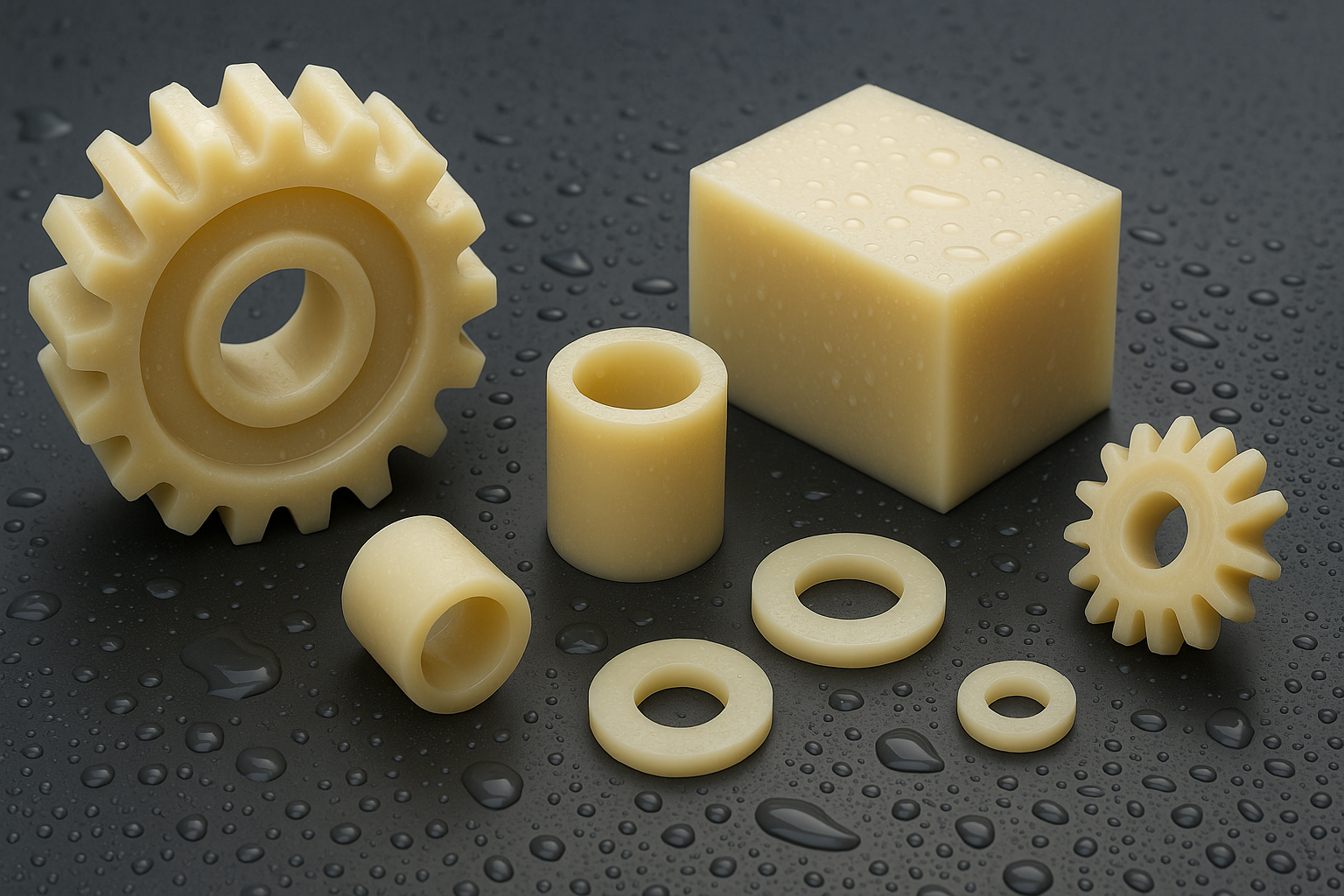

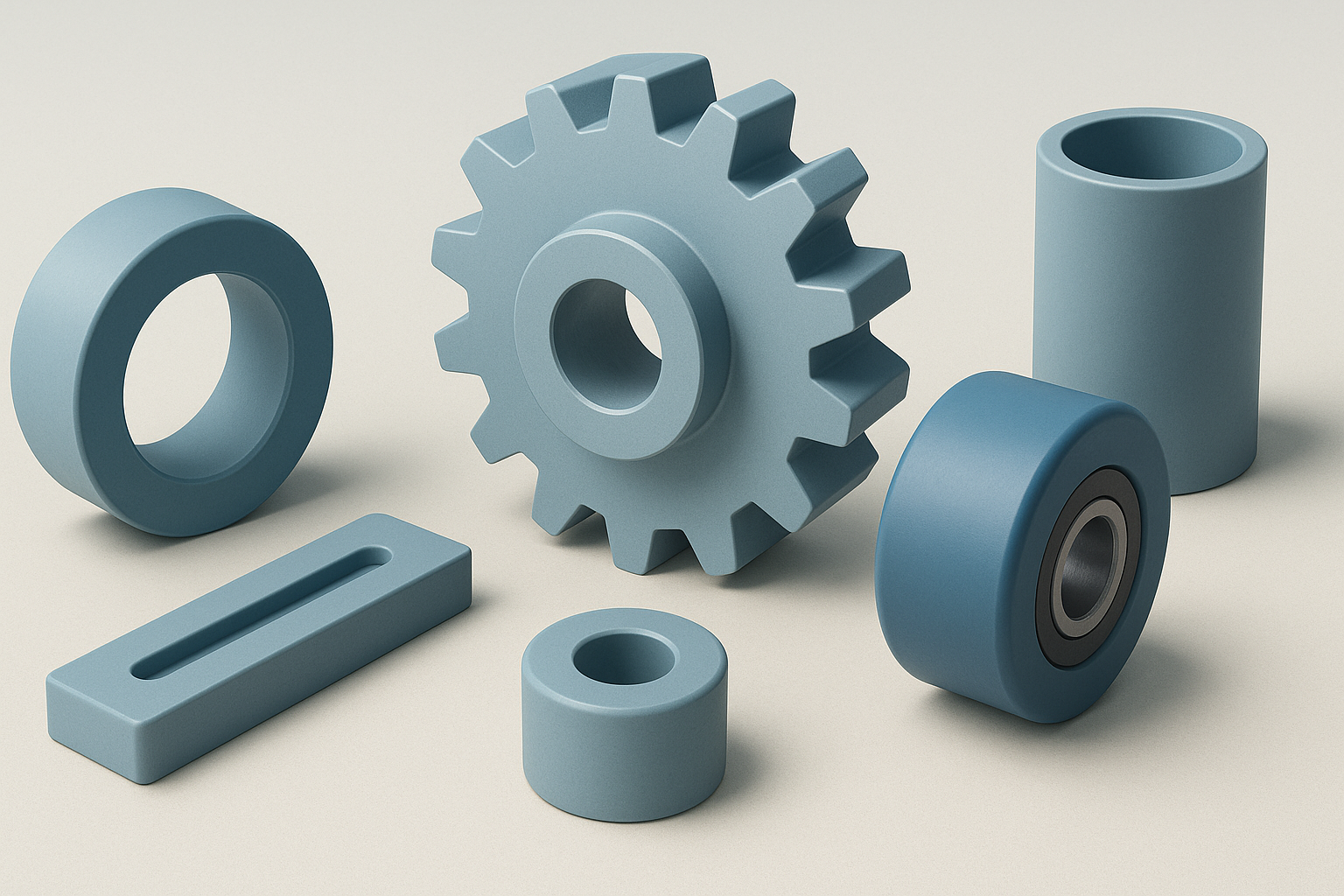

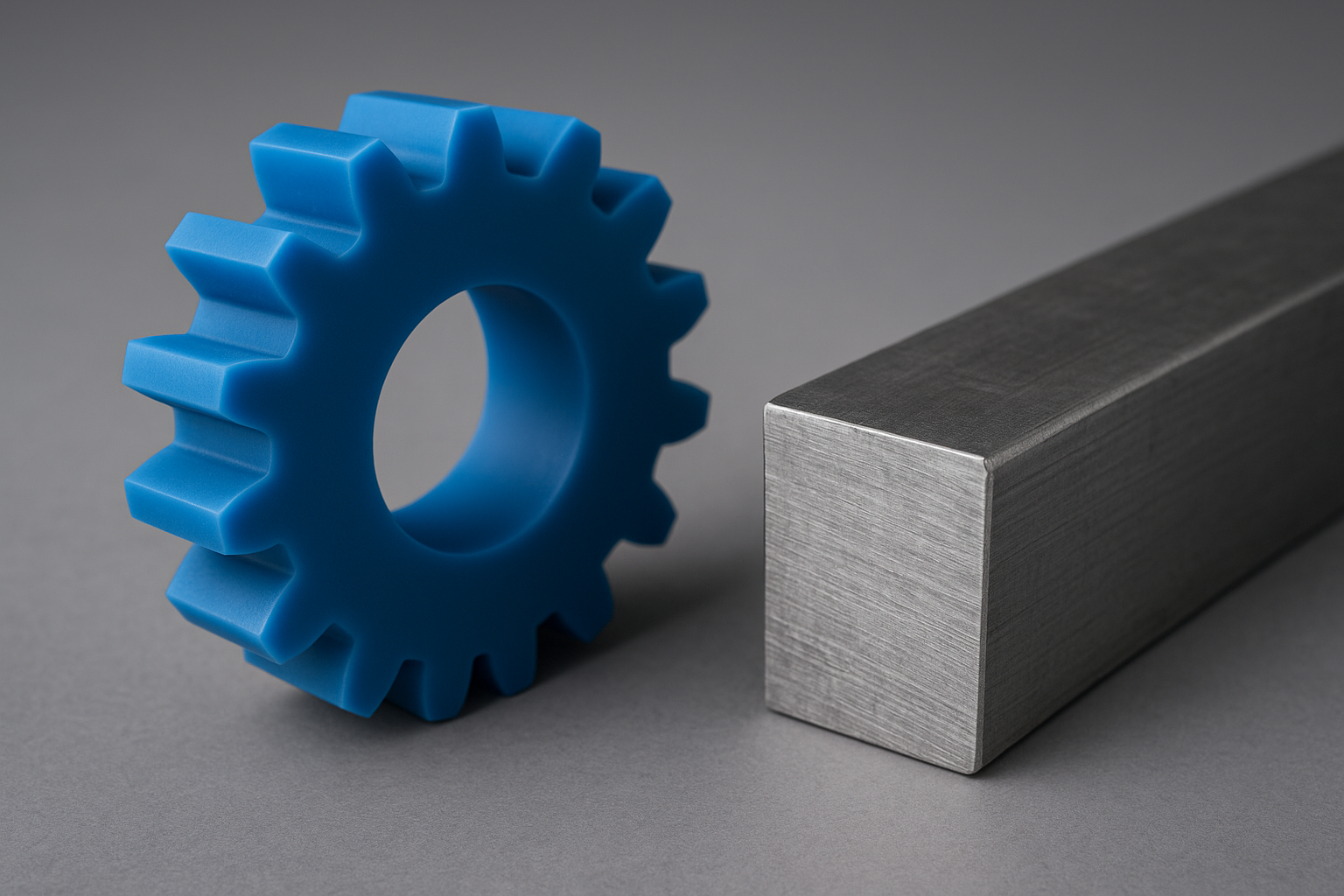

MC Nylon vs. Steel: Why Plastic Can Be the Superior Choice

2025-08-16

Introduction

To many, steel symbolizes strength, while plastic suggests compromise. Yet, MC Nylon (monomer cast nylon) surpasses steel in numerous industrial applications, particularly for components that move, slide, or wear over time. This article explores why MC Nylon is a smart alternative to steel, helping you make informed material decisions.

1. Weight: A Key to Efficiency

MC Nylon is approximately 1/7th the weight of steel, reducing strain on motors, bearings, and support structures in systems involving movement, rotation, or lifting. This impacts:

- Energy Consumption: Lighter parts reduce power usage.

- Motor Wear: Lower loads extend motor lifespan.

- System Inertia: Less mass eases start-stop stress.

- Downtime: Reduced strain minimizes maintenance needs.

Conclusion: Lighter MC Nylon enhances efficiency and reduces wear.

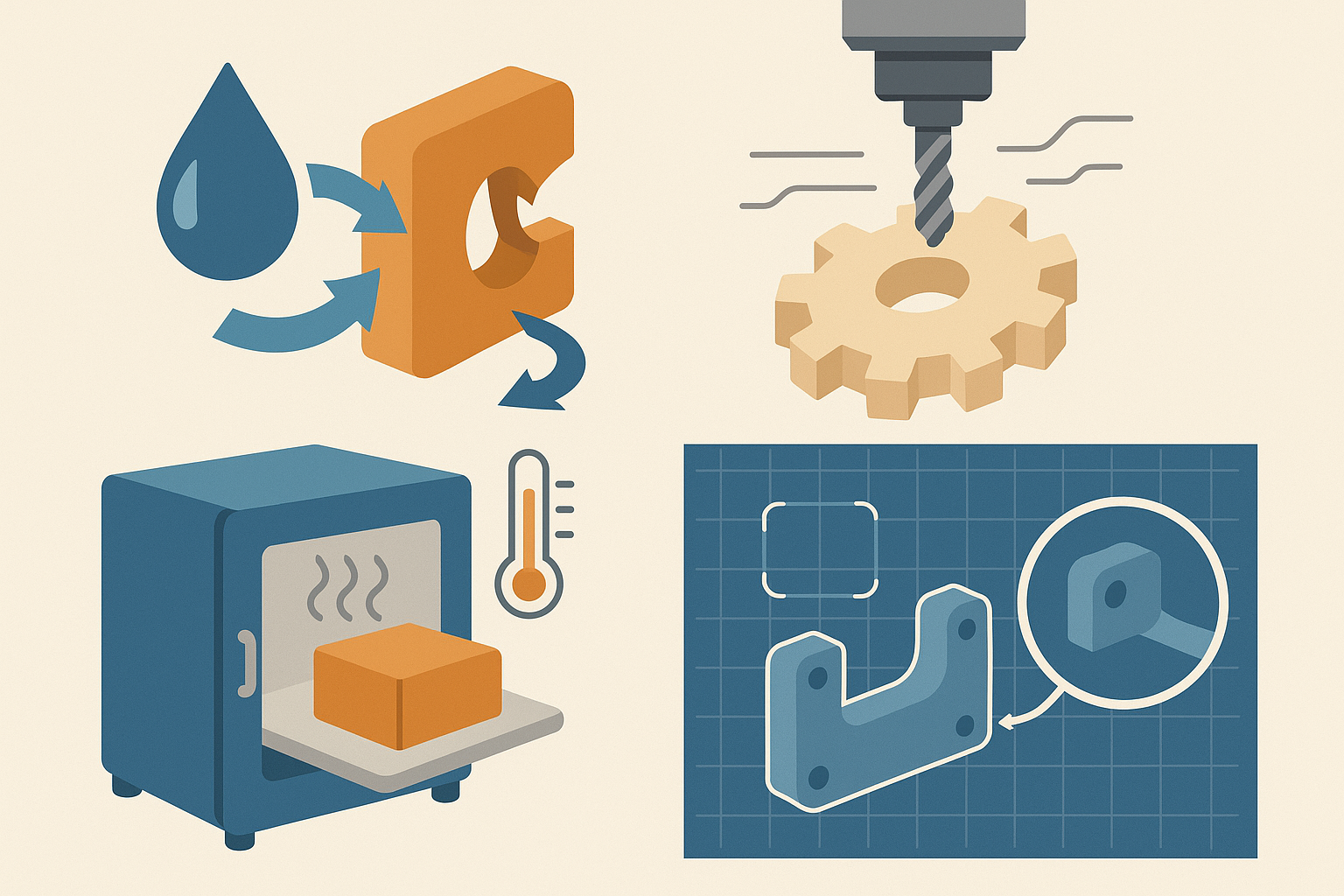

2. Self-Lubrication: Lower Maintenance Costs

Steel components require grease or oil to prevent seizing or overheating. MC Nylon, particularly oil-filled variants, offers self-lubricating properties, ideal for:

- Hard-to-Reach Equipment: Such as high or enclosed systems.

- Dusty or Dirty Environments: Where grease attracts debris.

- Food or Pharmaceutical Industries: Avoiding lubricant contamination.

MC Nylon’s low-friction properties ensure quieter operation and longer-lasting components.

Data Support: Oil-filled MC Nylon has a friction coefficient of 0.1-0.3, compared to unlubricated steel’s 0.5-0.8 ScienceDirect, “Friction Properties of MC Nylon in Industrial Applications”, 2024.

3. Impact Resistance: Toughness Over Hardness

Steel is rigid but prone to dents or cracks under sudden impacts. MC Nylon’s toughness allows it to flex and absorb shock without permanent damage, critical for:

- Gears with Variable Loads: Handling dynamic stress.

- Bearings in Vibrating Systems: Reducing fatigue failure.

- Components Facing Impacts: Preventing cascading damage.

Data Support: MC Nylon’s impact strength reaches approximately 10-20 kJ/m², outperforming steel’s brittleness under dynamic impacts.

4. Corrosion-Free: Thriving in Harsh Environments

MC Nylon is inherently corrosion-resistant, unlike steel, which requires coatings or treatments. It excels in:

- Marine Equipment: Such as ship components.

- Food Processing Lines: Meeting hygiene standards.

- Agricultural Machinery: Resisting fertilizers and chemicals.

Case Study: MC Nylon reduces maintenance costs by up to 70% in marine applications Industry Today, “Cost-Saving Materials in Harsh Environments”, 2023.

5. Cost Comparison: Long-Term Economics

MC Nylon’s initial cost may exceed steel’s, but its self-lubrication, corrosion resistance, and low maintenance reduce long-term expenses. Studies show MC Nylon components lower maintenance costs by 20-50% in harsh environments, with more efficient production for large parts.

6. Sustainability: Environmental Considerations

MC Nylon is recyclable, though the process is complex. Using recycled or bio-based nylon reduces resource consumption. Compared to steel’s high-energy production, MC Nylon’s lifecycle is more environmentally friendly, lowering the carbon footprint.

7. Limitations of MC Nylon

MC Nylon is not a universal solution. Steel is preferable for:

- High-Precision Components: Requiring ultra-tight tolerances.

- High-Temperature Environments: MC Nylon softens above 120-130°C.

- Long-Term Static Loads: Potential deformation under constant pressure.

- Water Absorption: 1-3% water absorption in humid environments may cause dimensional swelling.

Understanding these limitations ensures smarter material choices.

Conclusion

MC Nylon is a superior choice for specific applications: lighter, quieter, cleaner, and more resilient than steel. In moving, sliding, or vibrating systems, it reduces costs, minimizes maintenance, and extends operational life. Reconsider steel as a default—MC Nylon may offer significant benefits.

Call to Action

Curious about MC Nylon’s real-world applications? Contact our material engineers for a free consultation or subscribe to our blog for industry insights!

References

TAG:

Related News

The Hidden Role of Moisture in MC Nylon Performance