MC Nylon vs POM: Which Is Better for Gears?

2025-07-24

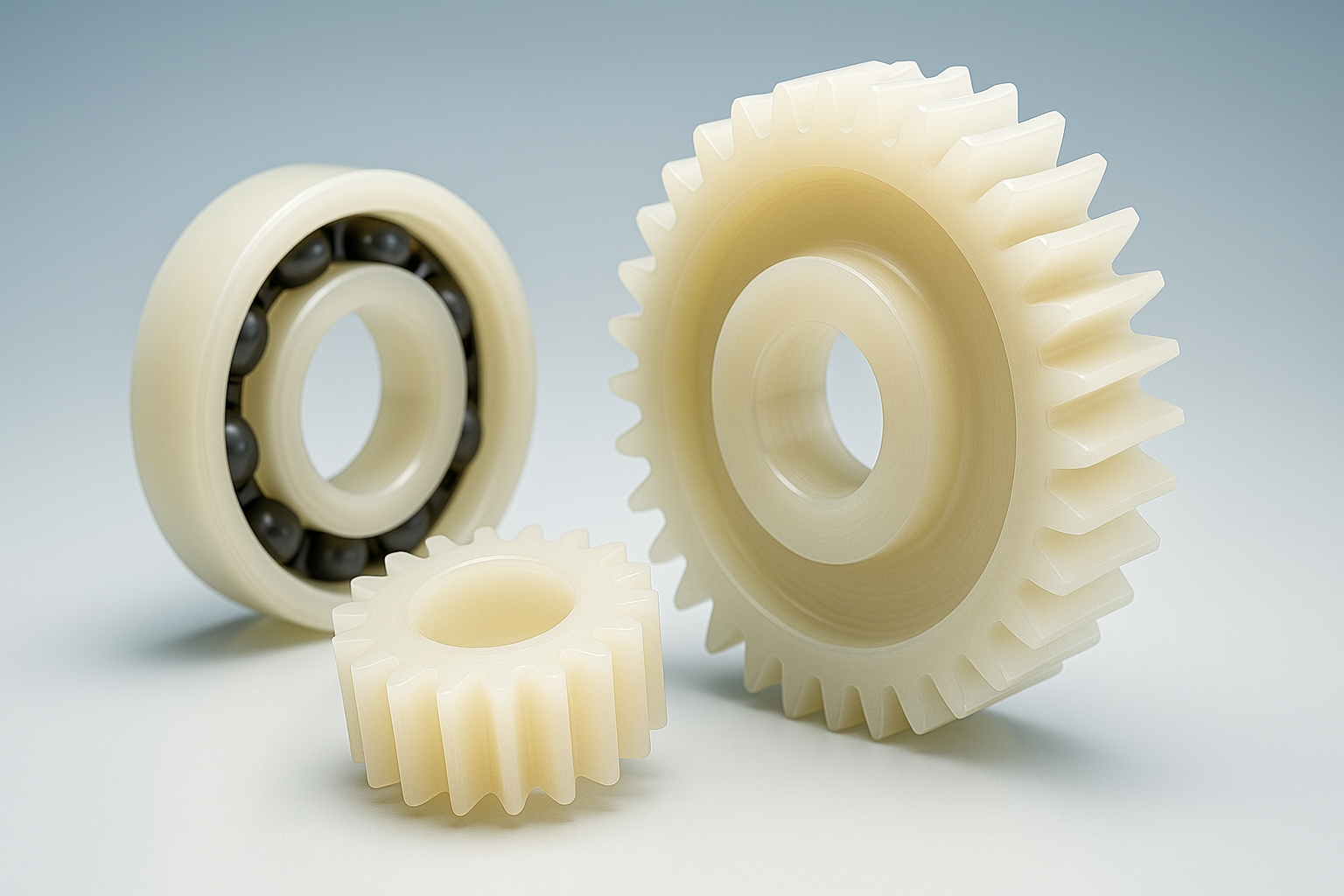

Intro

When designing a lightweight gearbox, you often reach a crossroads: choose MC Nylon or POM (acetal)? One touts superior wear resistance; the other excels in precision. This article uses a single table and a quick decision tree to sort it out in about three minutes.

1 Three Key Factors for Gear Materials

Strength – Can it handle shocks and sudden torque spikes?

Wear life – How long before the teeth thin out?

Noise level – Does it run smoothly and quietly?

Only technical term: Coefficient of friction – the lower the number, the smoother and quieter the gear runs.

2 Performance Comparison Table

| Metric | MC Nylon | POM | Note |

|---|---|---|---|

| Density (g/cm³) | 1.15 | 1.41 | About 20 % lighter |

| Coefficient of friction | 0.25 | 0.35 | MC Nylon is quieter |

| Continuous service temp (°C) | 120 | 100 | MC Nylon handles higher heat |

| Self‑lubrication | ★★★ | ★★ | Fewer lube cycles |

| Material cost | Slightly higher | Slightly lower | POM 10‑15 % cheaper |

3 Cost Breakdown

Material price – POM is typically 10 % or so cheaper by weight.

Machining cost – MC Nylon can be cast as a single large piece, cutting assembly labor.

Maintenance cost – With 1.5‑2× the wear life, MC Nylon means fewer change‑outs. In many mid‑to‑heavy‑duty applications, MC Nylon wins the long‑term cost race.

4 Decision Tree

High temperature or heavy load?

Yes → Choose MC Nylon

No → Next question

Need ultra‑high positional accuracy (±0.02 mm)?

Yes → Choose POM

No → Next question

Strict weight‑reduction target (>20 %)?

Yes → Choose MC Nylon

No → Next question

Rock‑bottom budget?

Yes → Choose POM

No → MC Nylon is generally preferred

5 One Pro, One Con Example

Construction‑equipment reduction gear

Swapping metal for MC Nylon cuts weight by 60 %, boosts service life by 40 %, and extends maintenance intervals by half a year.

Desktop 3D‑printer micro‑gear

POM delivers ±0.02 mm precision at a lower cost, saving about USD 5 per printer.

Wrap‑Up & CTA

In short: High heat, heavy loads, or aggressive weight savings → MC Nylon; tight precision and ultra‑low cost → POM.

Not sure which suits your gear set? Click below to request free samples and receive a tailored material‑selection report within 24 hours!

TAG:

Related News

The Marvel of Composite Materials: A Game Changer in Modern Manufacturing