Avoid Pitfalls! 5 Common Misconceptions about MC Nylon

2025-07-25

Intro

At many quotation meetings, eager newcomers hear “MC Nylon is light and wear‑resistant” and green‑light it on the spot—only to discover during mass production that temperatures run too high or parts come out undersized. The issue usually isn’t the material itself but five widespread misunderstandings. Let’s clear them up with a simple “Myth → Reality → Tip” format.

Myth 1|MC Nylon can handle any high temperature

Reality: Continuous service is about 120 °C; short spikes top out around 150 °C. Anything hotter demands premium materials like PEEK.

Tip: Verify your equipment’s peak operating temperature first, then decide whether MC Nylon fits.

Myth 2|Low density = low strength

Reality: MC Nylon weighs only one‑seventh as much as steel, yet its tensile strength is roughly 20 % higher than standard PA6. Light doesn’t mean weak.

Tip: Apply a proper safety factor in your design—no need to over‑thicken parts just because they’re light.

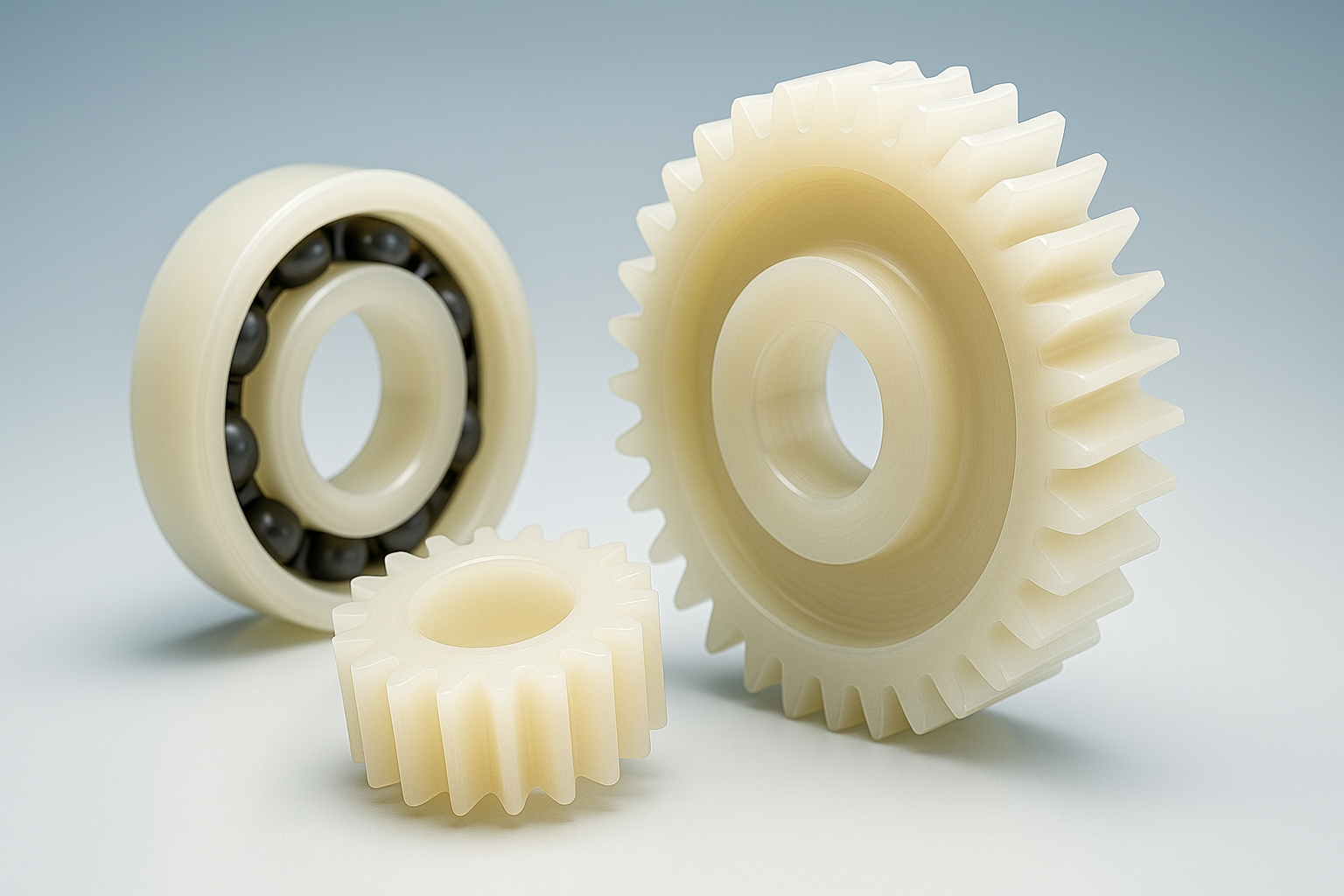

Myth 3|Self‑lubricating means zero lubricant

Reality: Medium‑to‑heavy‑load gears or bearings last 25 % longer when given a thin film of oil.

Tip: Run dry under light loads; add a light lubricant under heavier loads for maximum life at minimal cost.

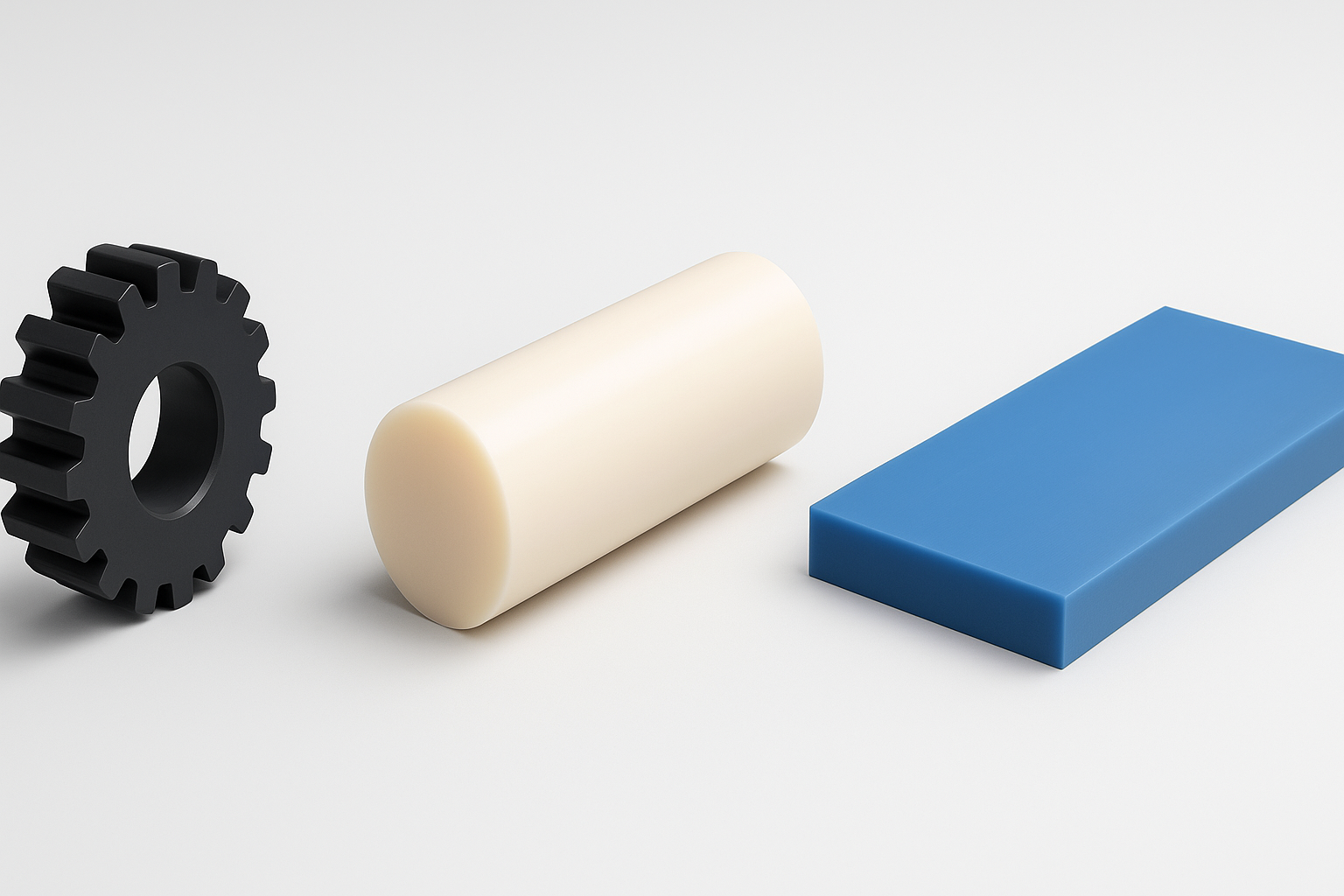

Myth 4|Different colors = different properties

Reality: Natural, black, and blue MC Nylon have nearly identical mechanical performance; color mainly helps batch ID or aesthetics.

Tip: Choose color for visibility or branding, not because you think “the pricey color is stronger.”

Myth 5|One‑shot casting guarantees perfect dimensions

Reality: Cast‑in shrinkage is about 0.5–1 %. Large parts that skip shrink compensation end up undersized, and critical holes still need finish machining.

Tip: Add shrink allowances in the mold, and re‑machine key datum holes if you need tolerances tighter than ±0.05 mm.

Conclusion & CTA

Master these five keys—temperature limits, strength planning, lubrication strategy, color facts, and shrink‑allowance—and MC Nylon will perform exactly as promised.

Still unsure whether MC Nylon matches your project? Click below to request a free sample and receive 24‑hour technical support!

TAG:

Related News

The Marvel of Composite Materials: A Game Changer in Modern Manufacturing