Contact

Contact: Manager Ma

Mid-section of Guanghua Road, Renze Economic Development Zone, Xingtai City, Hebei Province

MC nylon rod

- Product Description

-

Overview

MC Nylon (Monomer Casting Nylon) is a high-performance engineering plastic designed as a superior alternative to metals such as steel, copper, and aluminum alloys. With the concept of “replacing steel with plastic, superior performance”, it is widely used across diverse industries.

Key Features

Lightweight & Strong – Only one-seventh the weight of copper, yet capable of demanding applications.

Ultra-Low Friction – Friction coefficient is 8.8× lower than steel and 8.3× lower than copper.

Durable & Reliable – Self-lubricating, wear-resistant, corrosion-resistant, and insulating.

Extended Service Life – Increases the lifespan of machinery and parts by 4–5 times while lowering maintenance costs.

Versatile Applications – Suitable for pulleys, gears, bushings, bearings, guide wheels, impellers, valve bodies, rods, tubes, plates, and more.

Product Highlights

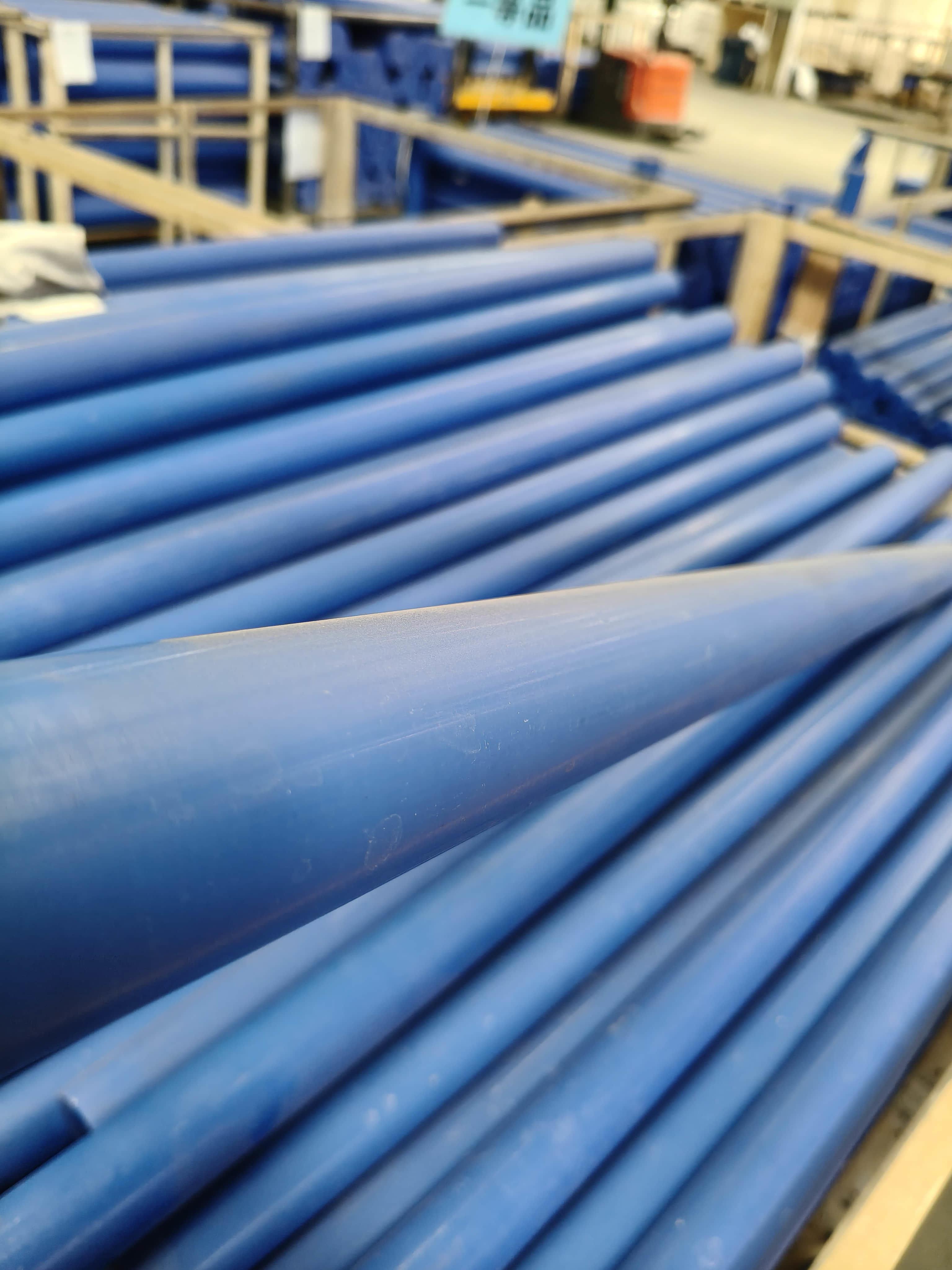

★ Premium Quality – Smooth surface, free of bubbles and impurities, with a density of 1.152 g/cm³.

★ Customizable Sizes – Standard length 1m, available in diameters from 30mm to 300mm.

★ Color Options – Blue, natural, black, green, red, and yellow; custom colors available.

★ High Surface Hardness – Ensures durability and consistent performance.Specifications

Color Options: Blue / Natural / Black / Green / Red / Yellow (customizable)

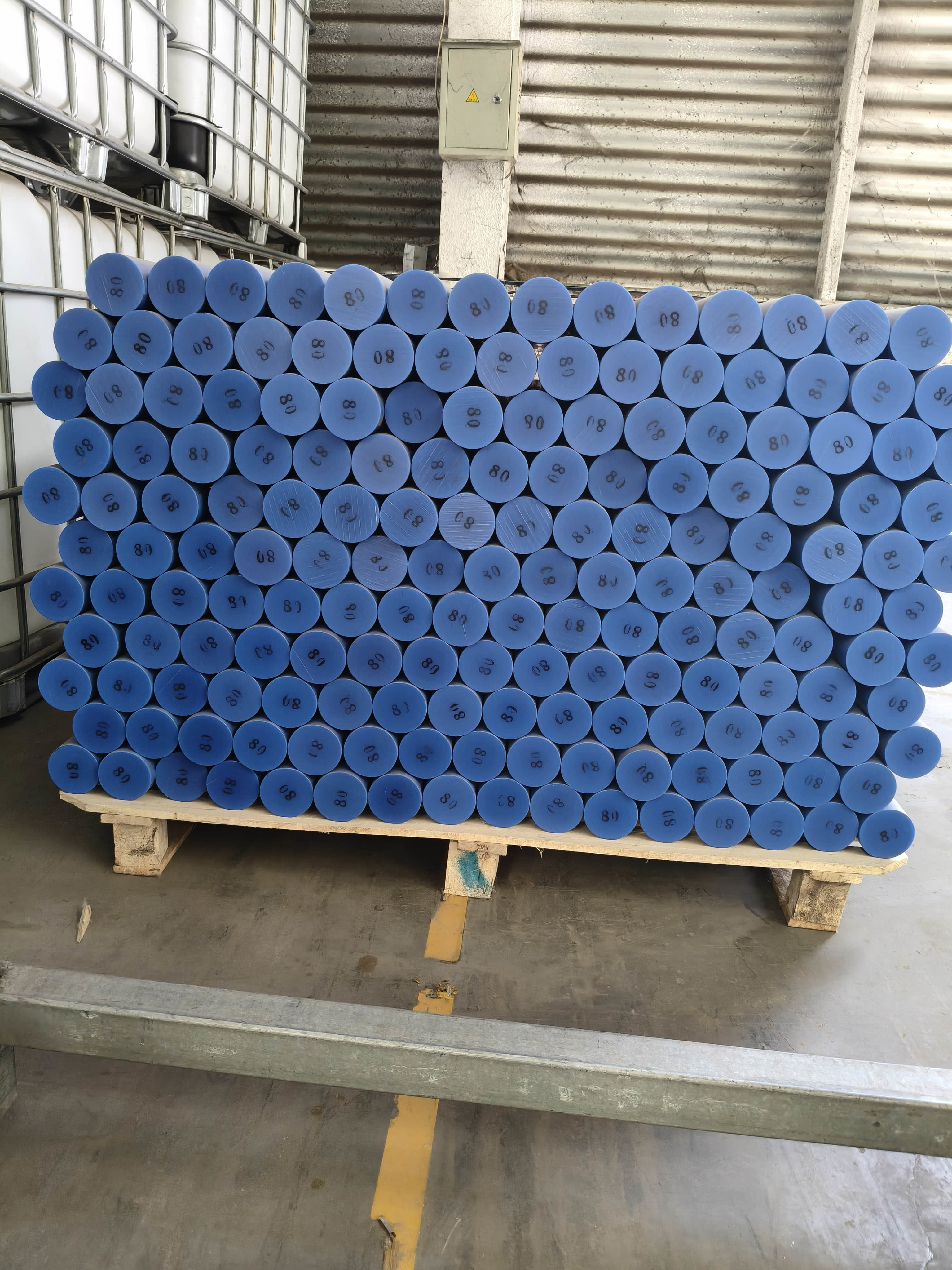

Quality: Smooth surface, stable dimensions, free of bubble defects

Diameter (mm) Diameter Tolerance (mm) Unit Weight (Kg) Diameter (mm) Diameter Tolerance ( mm ) Unit Weight (Kg) 30 +0.5+1.5 0.85 140 +1.2+4.1 18.46 35 +0.5+1.5 1.15 150 +1.2+4.1 21.2 40 +0.5+1.5 1.51 160 +1.3+4.5 24.12 45 +0.5+1.5 1.91 170 +1.3+4.5 27.22 50 +0.5+1.5 2.36 180 +2+7 30.52 55 +0.5+1.5 2.85 190 +2+7 34.01 60 +0.5+1.5 3.39 200 +2+7 37.68 65 +0.5+1.8 3.98 210 +2+7 40.98 70 +0.5+1.8 4.62 220 +2+7 46.80 75 +0.5+1.8 5.30 230 +2+7 50.96 80 +0.7+2.3 6.03 240 +2+7 55.16 85 +0.7+2.3 6.81 250 +2+7 59.16 90 +1+2.7 7.63 260 +2+7 63.86 95 +1+2.7 8.5 270 +2+7 69.08 100 +1+2.9 9.42 280 +2+7 74.29 110 +1+2.9 11.4 290 +2+7 79.50 120 +1+3.3 13.57 300 +2+7 87.31 130 +1.2+4.1 15.92 MC901/MC907 Rods Thickness/mm Thickness Tolerance/mm Standard Size/mm

1020×2020 Unit Weight/kg10 +0.5+2.5 24 20 +0.5+2.5 48 30 +0.5+3 72 40 +0.5+3 96 50 +0.5+3 120 60 +0.5+3.5 144 70 +0.5+4.5 168 80 +0.5+4.5 192 90 +0.5+4.5 216 100 +0.5+4.5 240 MC901/MC907 Plates Performance Indicators

Serial Number Item Unit Index Test Method Remarks 1 Tensile Strength MPa 76.6 ISO 527-2:2012 --- 2 Elongation at Break % 47 ISO 527-2:2012 --- 3 Compressive Strength MPa 118 ISO 604:2002 --- 4 Flexural Strength MPa 127 ISO 178:2010 --- 5 Shore Hardness Shore D 83 ISO 868:2003 --- 6 Melting Point ℃ 211 ISO 11357-3:2018 --- 7 Coefficient of Linear Thermal Expansion (25°℃-80°C) k- 96.5×10 -6 ISO 11359-2:1999 --- 8 Surface Resistivity Ω 4.84×10 15 IEC 60093:1980 --- 9 Volume Resistivity Ω·cm 9.19×10 15 IEC 60093:1980 --- 10 Relative Permittivity (100Hz) -- 3.91 IEC 60250:1969 --- 11 Density g/cm³ 1.152 ISO 1183-1:2004 --- 12 Water absorption % 0.8 IS0 62:2008 --- 13 Cantilever beam kJ/m² 9.3 ISO 180:2000 Fracture type; C 14 Coefficient of friction -- Static coefficient of friction: 0.150

Dynamic coefficient of friction: 0.128ISO 8295-1995 --- 15 Limiting oxygen index % 23.3 ISO 4589-2:2017 --- 16 Heat deflection temperature under load ℃ 67 ISO 75-1:2013 Flat at 120°C/h, 1.8MPa

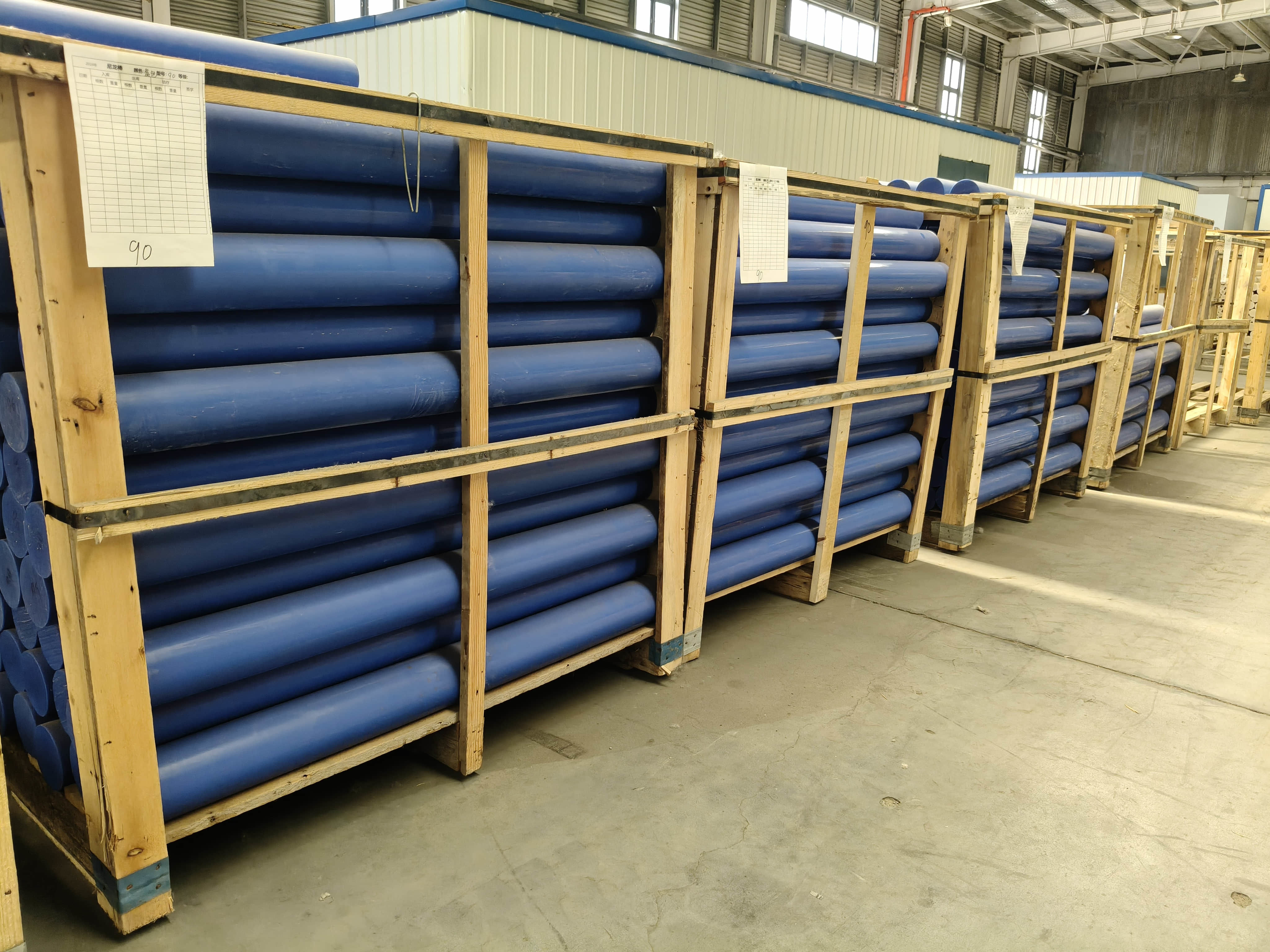

17 Dielectric strength KV/mm 17.8 IEC 60243-1:2013 --- Product packaging

Contact Us

TAG: