Contact

Contact: Manager Ma

Mid-section of Guanghua Road, Renze Economic Development Zone, Xingtai City, Hebei Province

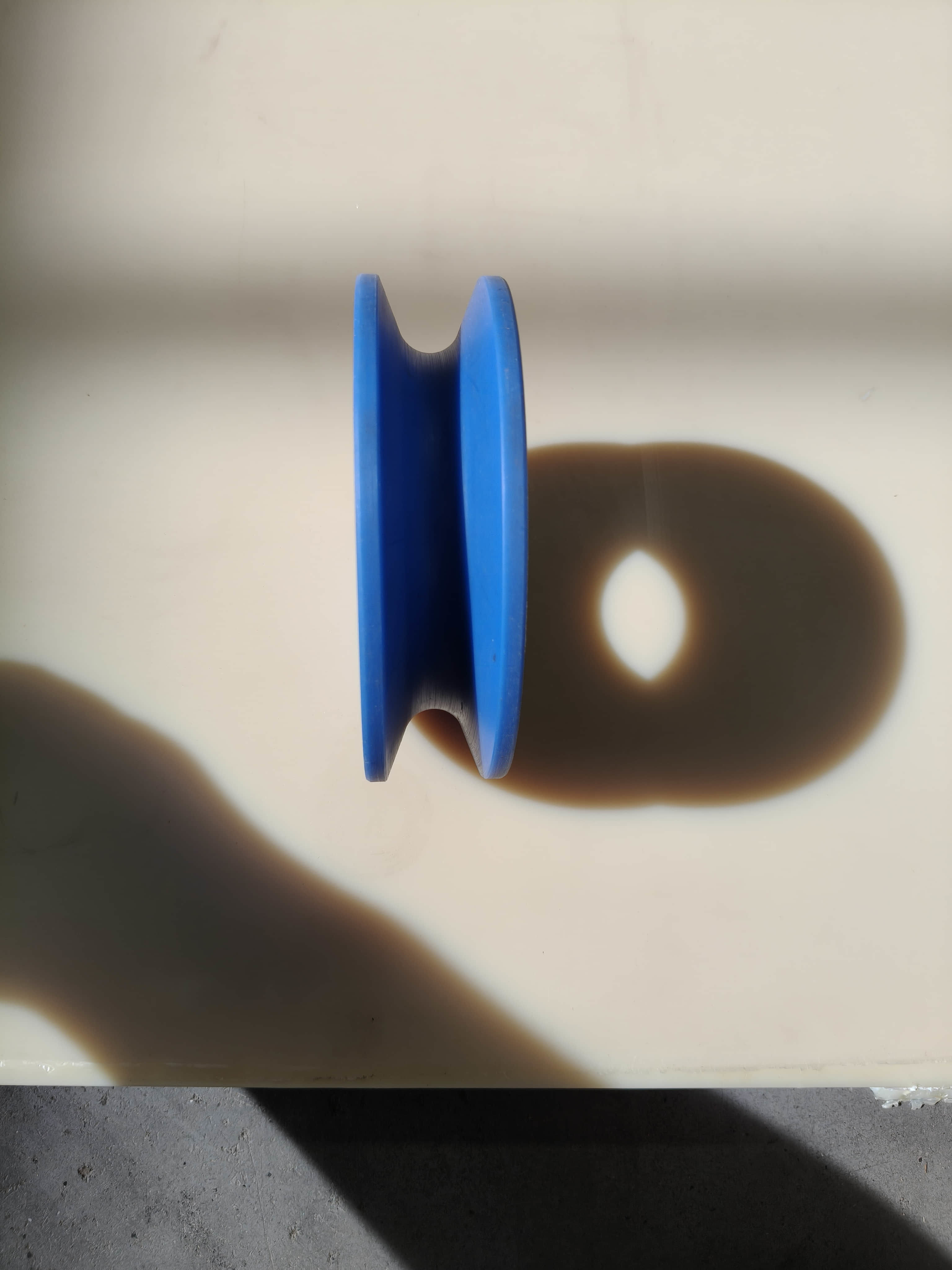

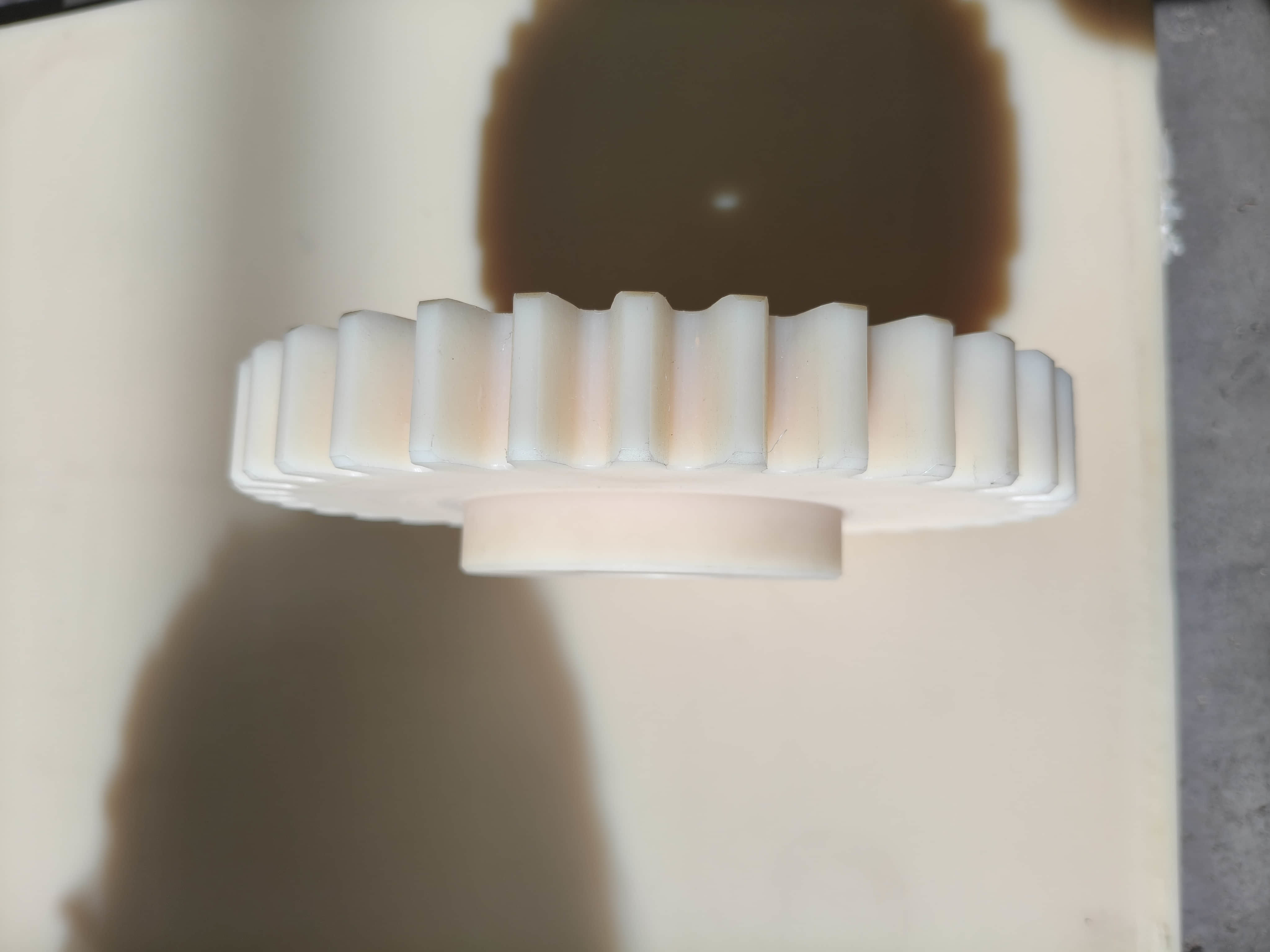

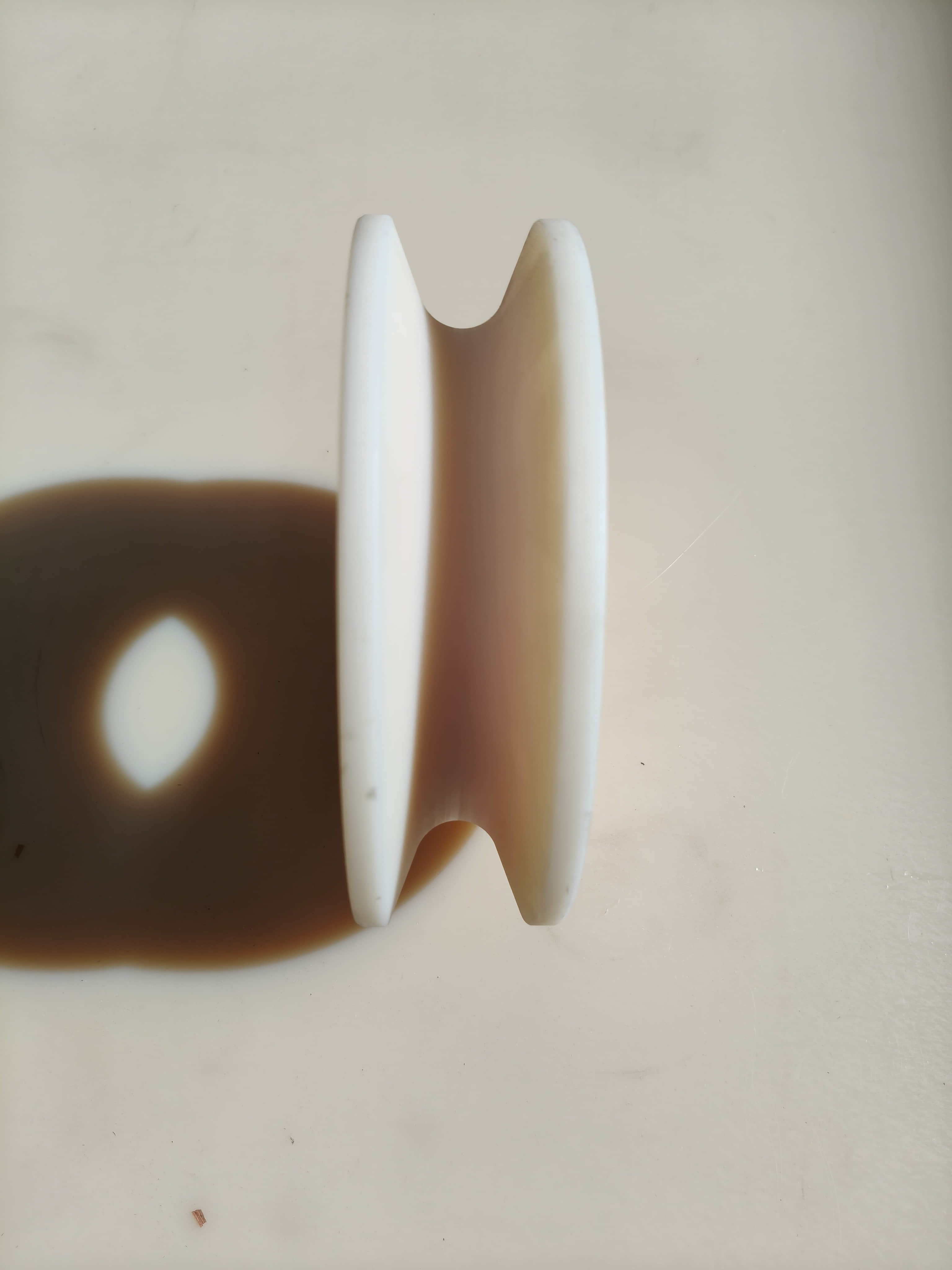

Casting nylon

- Product Description

-

I. Introduction

MC nylon processed components are manufactured by casting and precision machining to deliver durable, lightweight, and high-performance solutions for industrial use. Designed to replace metals such as copper, aluminum alloys, and stainless steel, MC nylon parts provide excellent strength, wear resistance, corrosion protection, and insulation while reducing weight and overall cost.

II. Manufacturing Principles

MC nylon parts are produced through a combination of casting and precision machining:

Casting – Molten nylon is poured into molds to form blanks in rods, sheets, or near-net shapes.

Precision Machining – CNC turning, milling, and drilling achieve tight tolerances and complex geometries.

Performance Enhancement – Additives such as glass fiber, lubricants, or stabilizers improve strength, wear resistance, or thermal stability.

Quality Control – Products undergo dimensional checks, hardness testing, and surface inspections to ensure consistency and reliability.

III. Key Performance Features

High Strength-to-Weight Ratio – Offers metal-like strength at a fraction of the weight.

Self-Lubricating – Reduces friction and minimizes the need for external lubrication.

Wear & Corrosion Resistance – Ensures reliable performance in abrasive and chemically aggressive environments.

Electrical Insulation – Provides safe, stable use in electrical and electronic assemblies.

Extended Service Life – Extends machinery lifespan 4–5 times compared with conventional metal components.

IV. Application Areas

Machinery – Gears, bushings, bearings, pulleys, rollers, and guide wheels for smoother operation and reduced wear.

Automotive – Transmission components, support elements, and vibration-damping parts, reducing weight and improving efficiency.

Electrical & Electronics – Insulating housings, connectors, and switch components, reliable in high-temperature and high-humidity conditions.

Industrial Equipment – Pump impellers, seals, and valve bodies for continuous operation in demanding environments.

Sports & Aerospace – Lightweight frames, protective panels, and auxiliary structures requiring strength and impact resistance.

V. Development Outlook

Eco-Friendly Materials – Development of recyclable and biodegradable nylon composites.

Advanced Performance – Use of nanofillers and flame-retardant additives to enhance thermal and environmental resistance.

Smart Manufacturing – Integration of automation, AI, and IoT for precision production and higher consistency.

Tailored Engineering – Customized material formulations and product designs to meet specific industry needs.

Contact Us

TAG: