Contact

Contact: Manager Ma

Mid-section of Guanghua Road, Renze Economic Development Zone, Xingtai City, Hebei Province

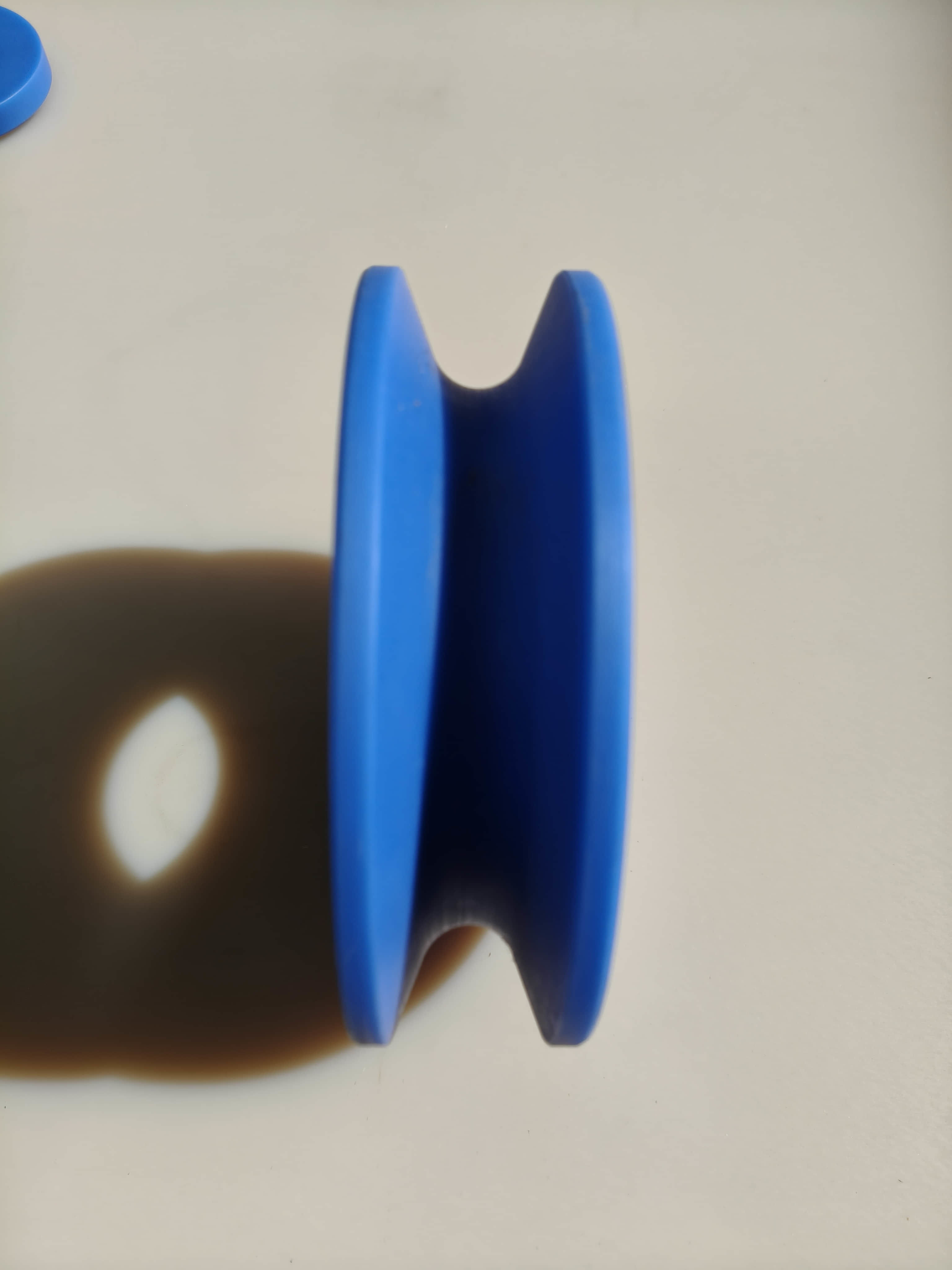

Casting nylon

- Product Description

-

▶ Product Highlights

Lightweight & Strong – One-seventh the weight of copper, yet comparable in strength.

Self-Lubricating – Reduces friction, noise, and wear without external lubricants.

Durable & Resistant – Excellent wear resistance, corrosion resistance, and electrical insulation.

Long Service Life – Extends component lifespan 4–5 times compared with metals, reducing maintenance costs.

Customizable – Available in multiple sizes, colors, and reinforced formulations.

▶ Processing & Manufacturing

MC nylon processed products are manufactured from high-quality blanks through advanced casting and precision machining:

CNC turning, milling, and drilling for complex geometries.

Grinding and finishing for high dimensional accuracy.

Optional heat treatment and surface finishing enhance durability.

Strict quality inspections ensure smooth surfaces and defect-free parts.

▶ Application Areas

Machinery: Gears, pulleys, bushings, bearings, rollers, guide wheels.

Automotive: Transmission components, vibration-damping parts, lightweight structures.

Industrial Equipment: Pump impellers, seals, valve housings, conveyor components.

Electronics: Insulating housings, switch covers, connectors.

Sports & Aerospace: Frames, protective panels, auxiliary structures, seals.

▶ Why Choose MC Nylon?

✔ Significant weight reduction compared with metals.

✔ Longer operating life with lower lubrication requirements.

✔ Reliable in harsh environments, including chemical, humid, and high-voltage conditions.

✔ Reduced downtime and overall cost savings.▶ Future Outlook

Eco-Friendly – Recyclable and biodegradable nylon grades.

Enhanced Performance – Nanofillers for higher heat and flame resistance.

Smart Manufacturing – IoT- and AI-enabled machining for precision and efficiency.

Tailored Engineering – Customized formulations and designs for specific industry needs.

Contact Us

TAG: