Unveiling the Magic of Cast Nylon: Its Mechanism and Marvels

2025-08-20

Introduction to Cast Nylon

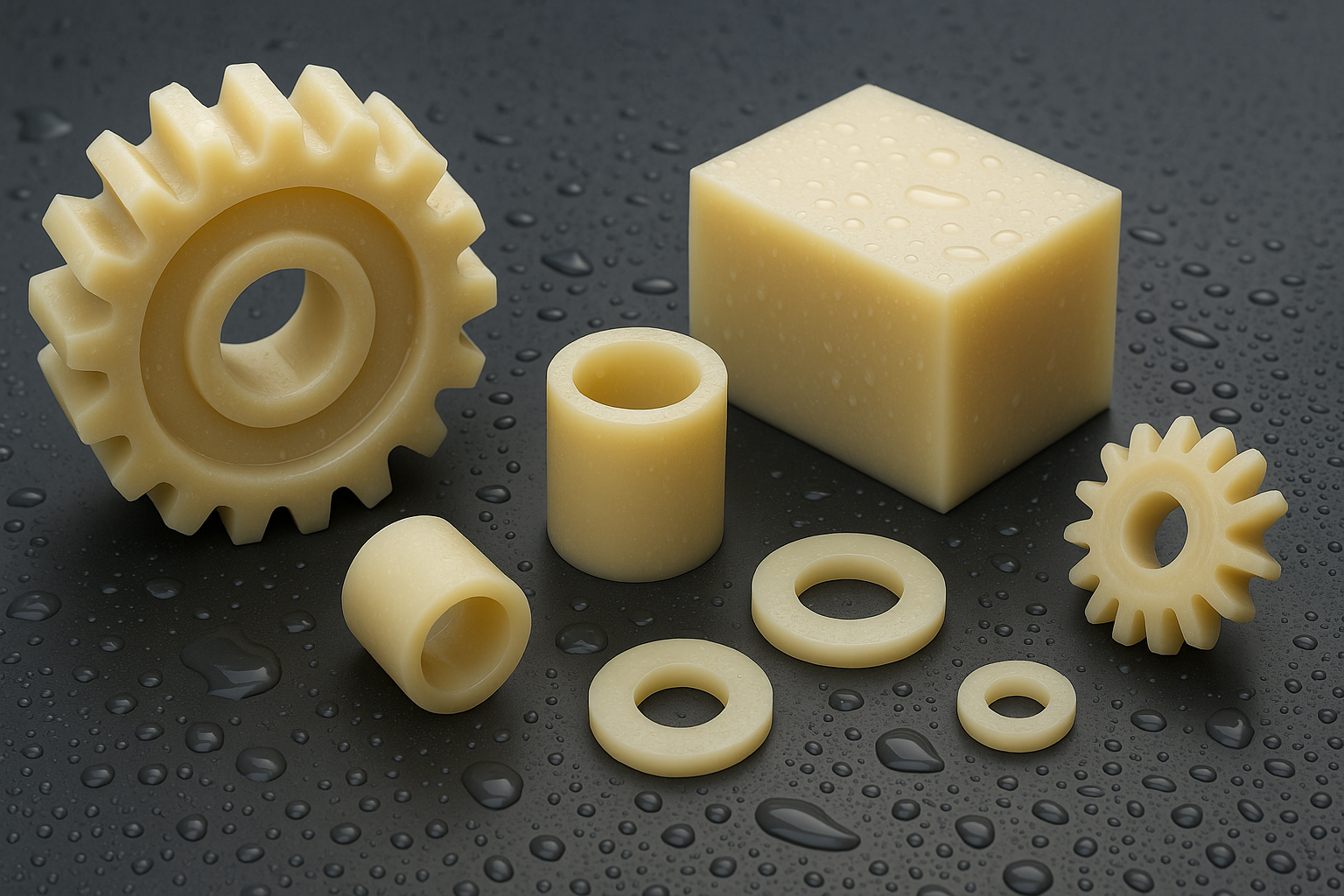

Hey there! Have you ever wondered what makes certain materials so incredibly strong yet versatile? Well, let's dive into the world of cast nylon! It's not just your average plastic; it's a game-changer in various industries. From gears to bearings, cast nylon has become the go-to material for many applications.

What Exactly is Cast Nylon?

So, what's the deal with cast nylon? In simple terms, it's a type of polyamide that's formed by casting a nylon resin into a mold. This unique process gives it superior qualities compared to other forms of nylon, making it a darling among engineers and manufacturers alike. You see, when it's cast, the molecules align in a way that enhances its strength and durability. Talk about a scientific marvel!

The Workings of Cast Nylon

Now, let's break down how this magical material works.Cast nylon is made via a polycondensation reaction, which might sound fancy, but it's essentially just a chemical process where small molecules join to form a larger one. When the nylon resin is poured into a mold, it solidifies as it cools, creating a robust and versatile end product. This method not only allows for intricate shapes but also minimizes waste. Win-win!

The Properties That Make it Shine

Alright, let's get down to the nitty-gritty. Why is cast nylon so popular? Here are a few standout properties:

- Strength: Its tensile strength is impressive, making it an excellent choice for load-bearing applications.

- Wear Resistance: It's like the Duracell Bunny of materials; it just keeps going and going, thanks to its excellent wear and abrasion resistance.

- Low Friction: When it comes to sliding surfaces, cast nylon is a smooth operator, reducing friction and wear in mechanical systems.

- Chemical Resistance: Whether it's oil, grease, or other harsh chemicals, this material stands its ground.

Applications of Cast Nylon

Alright, let's not beat around the bush!Cast nylon is everywhere! From automotive parts to industrial machinery, it's hard to find a sector that doesn't benefit from its attributes. Here are just a few applications:

- Automotive Components: Think gears, bushings, and wear pads that need to endure extreme conditions.

- Industrial Machinery: It's used in conveyor systems, rollers, and other components that require durability.

- Marine Applications:Cast nylon is resistant to saltwater, making it ideal for boat parts and marine hardware.

Benefits of Using Cast Nylon

Now, let's talk about why you should consider using cast nylon in your next project. Here's the scoop:

- Cost-Effective: While the initial investment might be a tad higher than other materials, its longevity means you'll save in the long run.

- Customization: With the ability to cast into various shapes and sizes, it's incredibly versatile.

- Environmentally Friendly: The casting process generates less waste, making it a more sustainable choice.

Final Thoughts

So, there you have it!Cast nylon is a remarkable material that combines strength, versatility, and cost-effectiveness. Its unique casting process not only enhances its properties but also opens up a world of possibilities for various applications. If you're considering materials for your next project, don't overlook the wonders of cast nylon; it's truly a powerhouse!

TAG:

Previous

Previous:

Related News

Unveiling the Magic of Cast Nylon: Its Mechanism and Marvels