Contact

Contact: Manager Ma

Mid-section of Guanghua Road, Renze Economic Development Zone, Xingtai City, Hebei Province

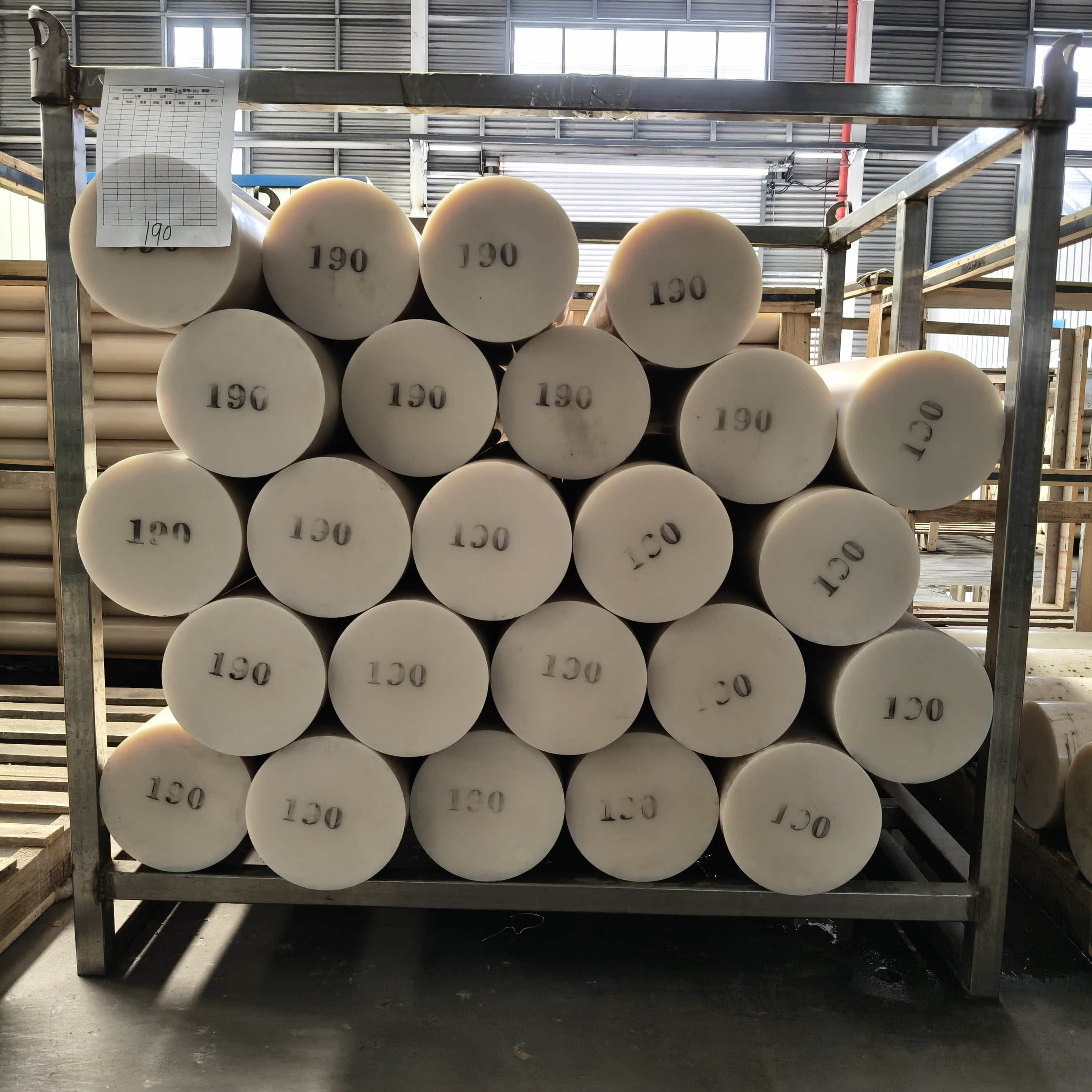

Casting nylon

- Product Description

-

I. Product Concept

MC nylon processed components are manufactured through casting, machining, and finishing techniques. Designed to replace bronze, copper, and steel, these products combine high strength with low weight, ensuring reliable performance across industries.

II. Production Approach

MC nylon finished parts are produced through a streamlined workflow:

Material Preparation – High-purity nylon resins are selected; reinforcements such as glass fiber, lubricants, or stabilizers can be added to enhance performance.

Casting & Forming – Nylon melt is poured into molds to create semi-finished blanks in rods, sheets, or custom profiles.

Precision Machining – CNC turning, milling, drilling, and grinding shape parts to tight tolerances and complex geometries.

Post-Processing – Heat treatment, trimming, polishing, and quality inspections deliver smooth surfaces, dimensional stability, and defect-free results.

III. Core Advantages

Lightweight & Strong – One-seventh the weight of copper, yet capable of heavy-duty use.

Wear-Resistant & Self-Lubricating – Reduces friction and enhances efficiency without frequent external lubrication.

Corrosion Resistance & Electrical Insulation – Performs reliably in chemically aggressive, humid, and electrical environments.

Cost-Effective & Durable – Extends service life 4–5 times longer than metal parts, lowering maintenance costs.

Flexible Customization – Sizes, colors, and material grades tailored to specific engineering needs.

IV. Typical Applications

Machinery – Gears, worm wheels, bushings, bearings, pulleys, rollers, guide wheels.

Automotive – Transmission parts, support components, vibration-damping elements.

Industrial Equipment – Pump impellers, seals, valve housings, conveyor components.

Electronics – Insulating housings, switch bodies, connectors.

Sports & Aerospace – Lightweight frames, protective panels, auxiliary structures, seals.

V. Market Outlook

Eco-Friendly Materials – Development of recyclable and biodegradable nylon composites.

Enhanced Performance – Nanofillers and additives to improve thermal resistance, flame retardancy, and weatherability.

Smart Manufacturing – Use of automation, AI, and IoT for greater precision and efficiency.

Tailored Solutions – Custom formulations and product designs to meet specific industry requirements.

Contact Us

TAG: